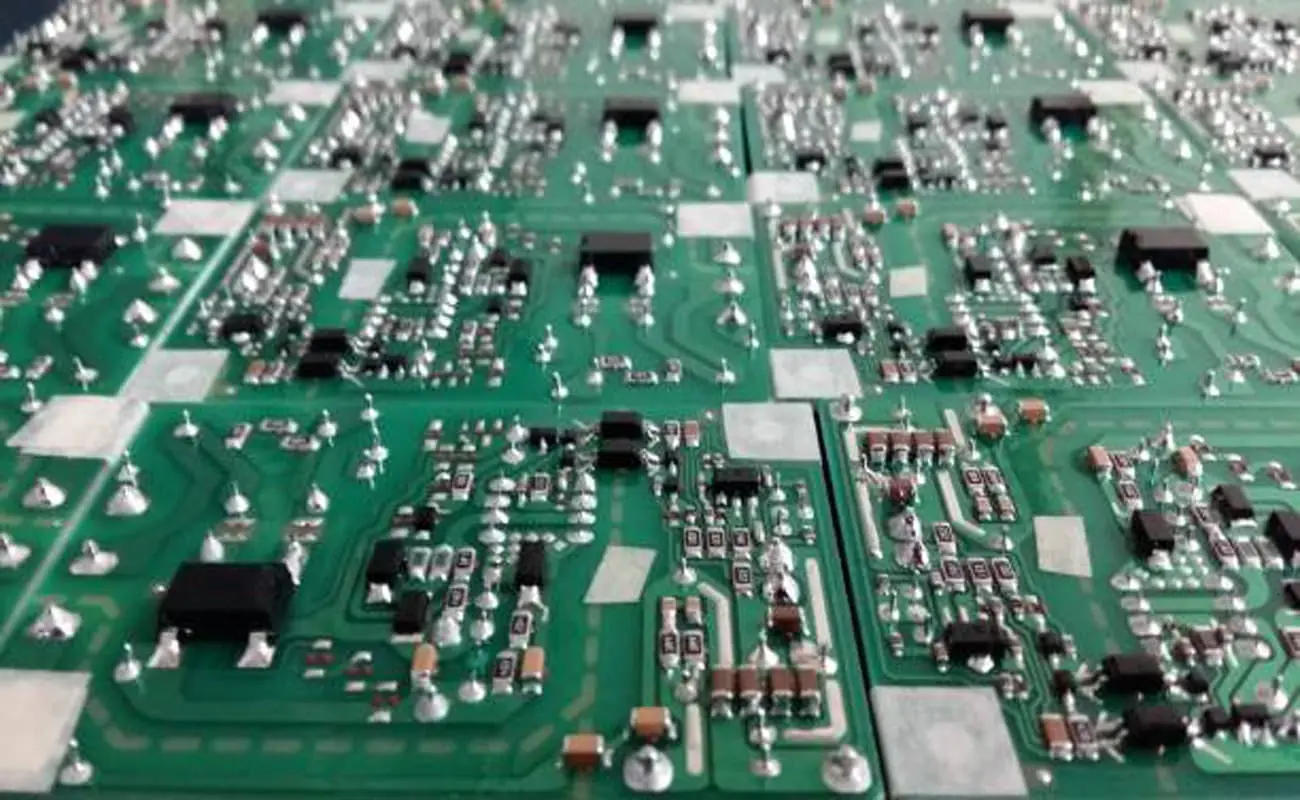

Trong PCBA (Hội đồng mạch in) ngành công nghiệp, vấn đề chất lượng là mối quan tâm nghiêm trọng ảnh hưởng đến cả khách hàng và nhóm nội bộ. Đảm bảo mọi bộ phận hiểu thuật ngữ IPC cơ bản là điều cần thiết để duy trì các tiêu chuẩn chất lượng cao và giảm thiểu các lỗi tốn kém. Fullhong thường xuyên tổ chức các buổi đào tạo nội bộ để giúp nhân viên hiểu rõ những khái niệm quan trọng này. Bài viết này cung cấp tài liệu tham khảo rõ ràng về các thuật ngữ IPC chính trong sản xuất PCBA và đảm bảo chất lượng.

1. Bề mặt bảng

Bên chính (Mặt chính): Phía của PCB với mật độ thành phần phức tạp nhất hoặc cao nhất. Trong công nghệ xuyên lỗ (Tht), đây cũng có thể được gọi là phía thành phần hoặc phía kết thúc hàn.

Bên thứ cấp (Phía đối diện): Mặt đối diện với mặt chính. Trong THT, thường được gọi là mặt hàn hoặc mặt bắt đầu hàn.

Bề mặt hàn

-

Hàn bắt đầu bên: Phía PCB nơi hàn đầu tiên được áp dụng. Trong hàn sóng, hàn nhúng, hoặc kéo hàn, đây thường là mặt phụ. Để hàn thủ công, nó có thể ở một trong hai bên.

-

Bên chấm dứt hàn: Phía nơi chất hàn chảy vào lỗ. Trong các quy trình tự động, đây thường là mặt chính.

2. Khiếm khuyết và Điều khoản kiểm tra

bong bóng: Không khí hoặc các chất dễ bay hơi được bao bọc hoàn toàn trong vật liệu phủ hoặc giữa các bộ phận và Bề mặt PCB.

Cầu nối bong bóng: Bong bóng bị kẹt giữa các dây dẫn hoặc bộ phận liền kề, tạo ra các kết nối ngoài ý muốn.

Mối hàn lạnh: Xám, kết nối hàn xốp do làm ướt kém, không đủ nhiệt, hoặc ô nhiễm.

Bóng hàn: Tàn dư hàn hình cầu nhỏ còn sót lại sau khi hàn nóng chảy lại.

3. Dây dẫn và dây điện

Dây dẫn chung: Các dây dẫn mang dòng điện giống nhau, điện áp, Tính thường xuyên, hoặc chức năng (ví dụ., đường tín hiệu, dấu vết, dây điện, hoặc thiết bị đầu cuối).

Dây dẫn không phổ biến: Dây dẫn có đặc tính điện khác nhau cho đến khi được xác định rõ ràng trong tài liệu kỹ thuật.

Sự chồng chéo dây dẫn: Một dây dẫn quấn trên 360° tự cắt ngang mà không tiếp xúc đúng với thiết bị đầu cuối.

Bao bọc dây dẫn: Dây dẫn quấn quanh 360° trong khi vẫn duy trì tiếp xúc đầu cuối thích hợp.

Giảm căng thẳng: Đảm bảo dây dẫn hoặc dây điện bị chùng để giảm căng thẳng cơ học.

xoắn (xoắn): Các chỗ uốn cong hoặc biến dạng quá chặt ở dây hoặc dây dẫn thành phần không thể duỗi thẳng được.

Dây nhảy/Dây Z: Dây được lắp đặt theo công nghệ xuyên lỗ (PTH) như một phần của thành phần.

4. Linh kiện và lớp phủ

Lớp phủ hình mặt trăng (Thành phần): Vật liệu đóng gói kéo dài từ đế thành phần lên dây dẫn, bao gồm cả gốm sứ, epoxy, hoặc các hợp chất đúc tổng hợp.

Thiếu thành phần: Bất kỳ thành phần nào bị thiếu ở bất kỳ cấp độ sản phẩm nào đều được coi là khiếm khuyết.

F/i (Hình thức, Phù hợp, Chức năng): Đặc điểm của các bộ phận, mối hàn, các cụm lắp ráp phụ, hoặc các cụm mà lỗi có thể ảnh hưởng đến việc lắp đặt, độ tin cậy, hoặc hoạt động.

5. Quy trình thử nghiệm và sản xuất

Tài liệu kỹ thuật: Bất kỳ bản vẽ, thông số kỹ thuật, hoặc sơ đồ kỹ thuật được tạo ra trong quá trình thiết kế để làm rõ yêu cầu thiết kế.

Là (Mảnh vụn vật thể lạ): Bất kỳ vật lạ nào không liên quan đến thành phần hoặc hệ thống, chẳng hạn như các mảnh hoặc hạt.

Hàn Reflow xuyên lỗ: Quy trình bôi kem hàn vào các đầu cực xuyên lỗ bằng giấy nến hoặc ống tiêm, sau đó chỉnh lại dòng bằng các thiết bị gắn trên bề mặt (SMD). Còn được gọi là “ghim vào dán”.

Tại sao hiểu các điều khoản IPC lại quan trọng trong PCBA

Sự hiểu biết vững chắc về các tiêu chuẩn và điều khoản IPC cho phép các nhóm giảm thiểu các lỗi tốn kém và phải làm lại trong quá trình sản xuất, sắp xếp các nhóm đa chức năng theo tiêu chuẩn chất lượng, đảm bảo kiểm tra và quản lý lỗi nhất quán, và cải thiện giao tiếp với khách hàng và nhà cung cấp. Bằng cách tích hợp kiến thức IPC vào thực tiễn lắp ráp PCB công nghiệp, các công ty như Fullhong đảm bảo rằng mọi PCB đều đáp ứng các yêu cầu nghiêm ngặt về chất lượng và độ tin cậy.

Phần kết luận:

Chất lượng trong PCBA không chỉ là trách nhiệm của bộ phận kỹ thuật hoặc QA—đó là cam kết liên bộ phận. Nắm vững thuật ngữ IPC và kỹ thuật kiểm tra thích hợp là nền tảng để ngăn ngừa lỗi, nâng cao độ tin cậy, và duy trì sự hài lòng của khách hàng.

Để lại một câu trả lời