5G 등 첨단 기술의 급속한 발전으로, 일체 포함, 그리고 사물인터넷 (IoT), electronic products are facing increasingly stringent requirements for high-frequency signal transmission performance. In this race of “speed and precision,” printed circuit boards (PCB) serve as the cornerstone of electronic systems, making material selection critical. Among these materials, the Dielectric Constant (DK), also known as the relative permittivity (εr), is a core parameter that determines the electrical performance of PCBs in high-frequency environments. Improper Dk selection can lead to signal attenuation, crosstalk, timing deviations, and a series of issues that seriously affect product performance and reliability.

This article aims to provide an in-depth exploration of the critical impact of Dk on high-frequency signal transmission and offers practical strategies for PCB material selection to optimize design and enhance product performance. ✅ Unlock the secrets of Dk and safeguard your next high-frequency project.

1. Understanding the Dielectric Constant (DK): The Foundation of High-Frequency PCB Design

The Dielectric Constant (DK) describes a dielectric material’s ability to store electrical energy in an electric field, i.e., its polarization level. ~ 안에 PCB, it directly determines the propagation speed of signals along transmission lines.

-

Higher Dk values slow down signal propagation, while lower Dk values allow faster signal transmission.

-

For high-frequency signals, accuracy and stability of Dk are essential as they directly influence transmission delay and phase consistency.

An ideal high-frequency PCB material should have a low and stable Dk value to ensure minimal signal distortion.

Illustrations:

-

Dk value vs. signal propagation speed

-

Electric field distribution in dielectric material

2. Core Impacts of Dk on High-Frequency Signal Transmission

Dk affects not only signal speed but also the signal integrity (그리고) of high-frequency circuits. Its main impacts include:

⚡ Signal Propagation Speed and Delay

The propagation speed VpV_p of a signal on a PCB transmission line can be calculated as:

Vp=cDkV_p = \frac{기음}{\sqrt{DK}}

where cc is the speed of light. Clearly, a higher Dk slows down signal propagation, causing longer delays. In high-frequency systems, even minor timing differences can cause critical synchronization issues, especially in multi-channel or high-speed serial communication. Accurate Dk control effectively reduces propagation delays and ensures signal synchrony.

🔎 Characteristic Impedance Control

Characteristic impedance is another key concept in high-frequency PCB 설계. Impedance control involves designing the PCB trace width, 간격, and dielectric thickness to maintain impedance matching during signal transmission.

-

Dk directly affects trace characteristic impedance.

-

For microstrip and stripline structures, impedance Z0Z_0 is inversely proportional to Dk\sqrt{DK}.

-

Dk variations or inconsistencies can cause impedance discontinuities, resulting in signal reflections, waveform distortion, and energy loss.

Selecting PCB materials with stable Dk and tight tolerances is essential for precise impedance matching.

📢 Signal Loss and Dielectric Loss (Df)

Although Dk mainly affects speed and impedance, it is closely related to the Dissipation Factor (Df), which measures how much signal energy is absorbed and converted into heat.

-

Materials with higher Dk often exhibit higher Df (though not always).

-

High Df leads to greater insertion loss, especially in long-distance high-frequency transmission.

그러므로, in high-frequency applications, both Dk value and stability, as well as Df levels, must be carefully considered to minimize signal loss.

Illustrations:

-

Microstrip line structure

-

Impedance matching and reflected waveform

3. Dk Selection Strategies for High-Frequency PCB Materials

Choosing suitable high-frequency PCB materials is a multidimensional decision. Beyond Dk and Df, the following factors should be considered:

-

Dk Accuracy and Consistency: High-quality materials should have minimal Dk tolerance and maintain uniformity across the entire board, critical for impedance control.

-

Frequency and Temperature Stability: Ideal Dk values should remain stable across frequency ranges and temperature variations. Applications like millimeter-wave radar require Dk stability throughout the operational temperature range.

-

Material Type and Cost: High-frequency PCB materials include Rogers RO series, Taconic, Arlon, Isola, 등., each with different Dk, Df, 성능, 그리고 비용. PTFE-based substrates (예를 들어, 로저스) often have very low Dk and Df but are more challenging to process and expensive.

-

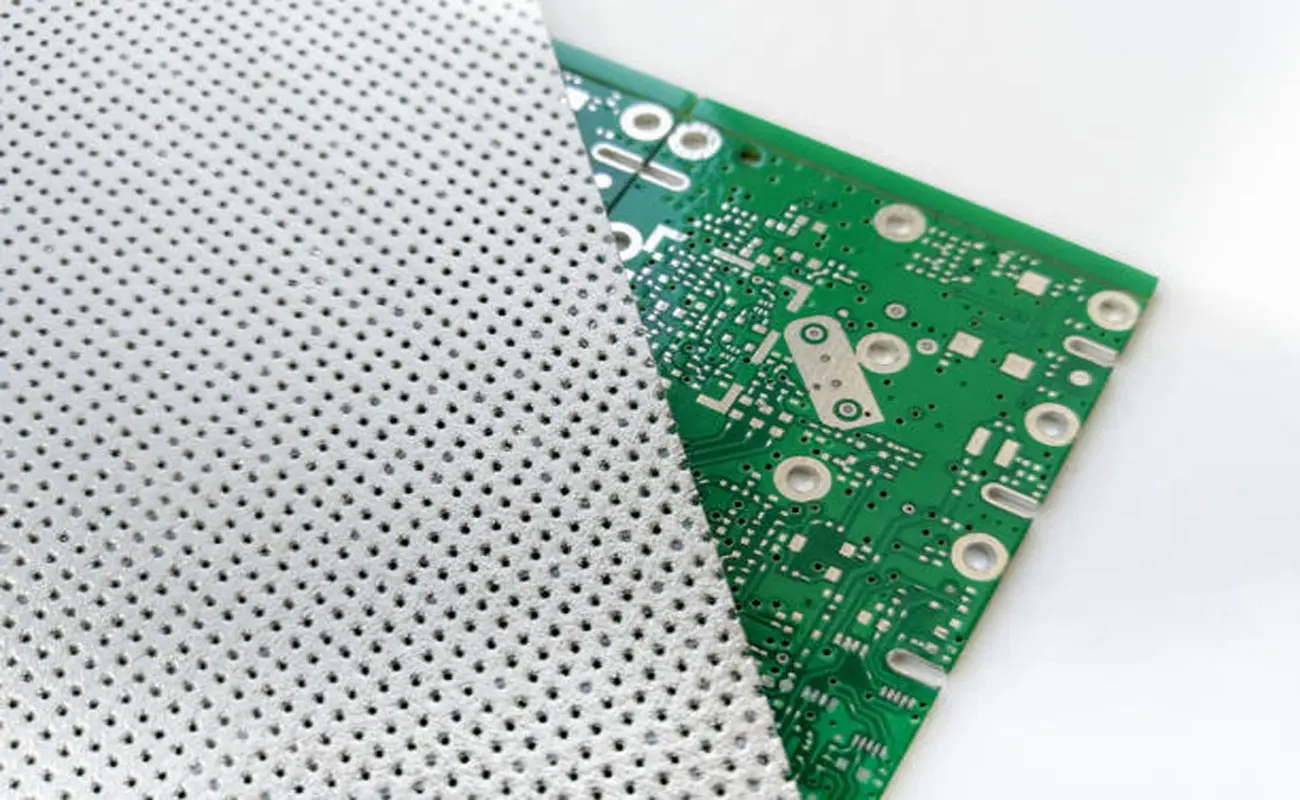

Copper Foil Properties: High-frequency signals propagate near the copper surface (skin effect). Smooth electrolytic copper (ED) or reverse treated foil (RTF) helps reduce signal loss.

-

Manufacturability: Even materials with excellent Dk performance must be feasible to process (교련, lamination) to maintain yield and control costs.

| 재료 | DK (유전 상수) | Df (Dissipation Factor) | tg (Glass Transition Temp) | CTE (Thermal Expansion) | 일반적인 애플리케이션 |

|---|---|---|---|---|---|

| Rogers RO4350B | 3.48 @ 10 GHZ | 0.0037 @ 10 GHZ | >280℃ | Z-axis: 32 ppm/°C | Microwave/RF circuits, power amplifiers, antennas, high-speed digital |

| Taconic RF-35 | 3.50 @ 10 GHZ | 0.0018 @ 10 GHZ | >315℃ | XY: 24 ppm/°C, Z: 77 ppm/°C | High-capacity commercial microwave/RF, radar, wireless communication, 항공 우주 & 방어 |

| FR-4 | 4.3–4.7 @ 1 GHZ | 0.015–0.030 @ 1 GHZ | 130–170°C | Z: 50–70 ppm/°C | General electronics, standard digital circuits, low-cost, non-high-frequency |

4. Fully Hong’s Professional Solutions and Advantages

In complex high-frequency PCB design and manufacturing, [완전 홍] leverages deep technical expertise and manufacturing capabilities to provide one-stop high-frequency PCB solutions, from material selection to finished product delivery.

We fully understand the critical role of Dk and other key parameters in high-frequency applications and can precisely recommend and source the most suitable PCB materials based on your project requirements. Our engineering team offers:

-

Professional High-Frequency Design Consultation: Assists with material Dk selection, impedance planning, and simulation to ensure signal integrity during the design phase.

-

Advanced Manufacturing Processes and Equipment: Equipped with high-precision lamination, pressing, and drilling systems, along with strict impedance testing to maintain Dk control and impedance matching accuracy.

-

Rigorous Quality Control System: From raw material inspection to final product delivery, every step undergoes performance testing, including Dk/Df and impedance testing, complying with IPC-A-600H and other international standards.

-

Extensive Project Experience: Successfully delivered high-quality PCB/PCBA solutions for communications, radar, 의료, and automotive high-frequency applications.

Why Choose Us?

We provide not only high-quality PCB products but also act as your reliable technology partner. [완전 홍] is committed to solving challenges in high-frequency PCB design and manufacturing. Through precise processes and data-driven decisions, we ensure superior product performance and controlled time-to-market. Our expertise transforms complex high-frequency design into a competitive advantage for your products.

Take Action Now! 📢 Whether you are developing 5G communication modules or designing next-generation ADAS systems, [완전 홍] offers customized PCB solutions tailored to your high-frequency project requirements.

One comment on “고주파 신호 전송 및 재료 선택에 대한 PCB 재료 유전 상수의 영향”

best backlinks for your website 2025

its good as your other content : D, regards for posting.