Akıllı telefonlarda, dizüstü bilgisayarlar, ve her gün güvendiğimiz arabalar, küçük yeşil bir devre kartı bu cihazların sinir sistemi görevi görür. İnsanlar hakkında konuştuğunda “devre kartları,” genellikle birbiriyle yakından ilişkili ancak farklı iki kavrama atıfta bulunurlar: PCB ve PCBA. Sadece bir harfle farklı olmalarına rağmen, elektronik ürünlerin "tasarım planı"ndan "işlevsel beynine" giden yolculukta iki önemli aşamayı temsil ediyorlar. Farklılıklarını anlamak, modern elektronik üretim dünyasına atılan ilk adımdır.

PCB nedir? Elektroniğin İskeleti

Bir PCB (Basılı devre kartı) tüm elektronik bileşenlerin temelini oluşturur. Karmaşık yollarla dolu, titizlikle tasarlanmış bir şehir haritası gibi düşünebilirsiniz. (iletken bakır izleri) ama hiçbir bina olmadan (elektronik bileşenler). Kurulun kendisi, tipik olarak fiberglas gibi yalıtım malzemelerinden yapılır, kazınmış bakır izleri aracılığıyla mekanik destek sağlar ve elektrik bağlantıları kurar. Kısacası, çıplak bir PCB'nin doğal bir işlevi yoktur; o yalnızca yaşamı bekleyen bir taşıyıcıdır. Tasarım ve uygulamaya bağlı olarak, PCB'ler tek katmanlı olabilir, çift katmanlı, veya elektronik cihazlarda artan minyatürleştirme ve gelişmiş işlevsellik taleplerini karşılamak için daha karmaşık çok katmanlı kartlar.

PCBA nedir?? Devrelere Hayat Vermek

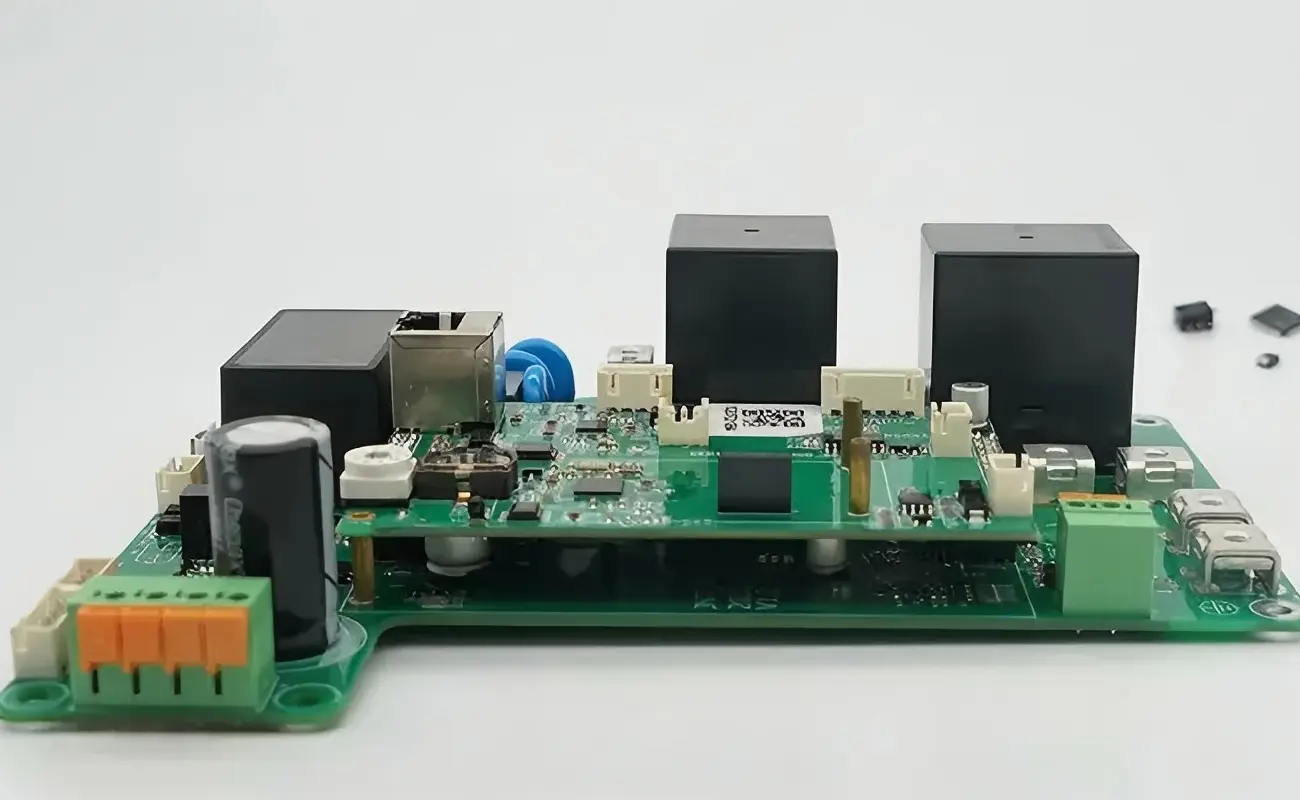

PCBA (Baskılı Devre Kartı Düzeneği) çipler gibi çeşitli elektronik bileşenlerin monte edilmesi sürecini ifade eder, dirençler, ve kapasitörler — lehimleme yoluyla boş bir PCB üzerine, tamamen işlevsel bir devre kartıyla sonuçlanır. PCB bir şehir planıysa, sonra bir PCBA tamamen inşa edilmiş bir yapıdır, binalarla dolu hareketli metropol, ışıklar, ve hareketli trafik. Bu aşamada, tahta bir “ruh” kazanır ve hesaplamalar yapabilir, süreç sinyalleri, ve belirli işlevleri yürütmek. Aslında, Günlük olarak kullandığımız her elektronik cihaz etkili bir şekilde çalışmak için PCBA'ya güvenir.

PCB ve PCBA Arasındaki Temel Farklılıklar

Açıklığa kavuşturmak için, farklılıklar açıkça görülüyor:

| Özellik | PCB (Basılı devre kartı) | PCBA (Baskılı Devre Kartı Düzeneği) |

|---|---|---|

| Tanım | İletken izleri olan ancak monte edilmiş bileşenleri olmayan çıplak bir tahta. | Tüm elektronik bileşenlerin lehimlendiği bir kart, tamamen işlevsel. |

| İşlev | Mekanik destek ve elektrik bağlantıları sağlar; doğal bir işlev yok. | Belirli elektronik işlevleri gerçekleştirir; cihazın çekirdek işlem birimi. |

| Kompozisyon | Yalıtım alt katmanı + bakır izleri | PCB + elektronik bileşenler (cips, dirençler, kapasitörler) + lehim |

| İmalat Aşaması | Elektronik üretiminde ilk adım; bileşen düzeyinde | PCB sonrası üretim; bitmiş veya yarı bitmiş ürüne yakın |

| Maliyet | Nispeten düşük; çıplak tahtanın üretim maliyeti | Daha yüksek; çıplak tahta içerir, bileşenler, toplantı, ve test maliyetleri |

Meclis Yolculuğu: Boş Şehirden Kalabalık Metropole

Bir PCB'yi güçlü bir PCBA'ya dönüştürmek son derece hassas bir montaj süreci gerektirir. Şu anda, iki ana teknik hakimdir: Yüzey montaj teknolojisi (SMT) modern elektronik üretiminde en yaygın yöntemdir. Küçük elektronik bileşenleri doğrudan PCB yüzeyine monte etmek için otomatik ekipman kullanır. İşlem, lehim pastasının bir şablon aracılığıyla PCB pedlerine basılmasını içerir, bileşenleri yüksek hızlı bir alma ve yerleştirme makinesiyle makaralardan yerleştirme, ve yeniden akışlı lehimleme işlemi kullanarak bileşenlerin kalıcı olarak sabitlenmesi. SMT, üretim verimliliğini ve montaj yoğunluğunu önemli ölçüde artırır, akıllı telefonlar gibi kompakt cihazlar için vazgeçilmez hale geliyor.

Delikten teknoloji (Tht) bileşen kablolarının önceden delinmiş deliklerden geçtiği daha geleneksel bir yöntemdir. PCB ve karşı tarafta lehimlenir. SMT hakim olurken, THT, yüksek mekanik mukavemet veya yüksek güç gerektiren uygulamalarda yaygın olarak kullanılmaya devam etmektedir, Konektörler ve büyük kapasitörler gibi. Birçok PCBA, her birinin güçlü yanlarından yararlanmak için hibrit bir montajda her iki tekniği de kullanır..

Uygulamalar ve Gelecek Trendleri

Tüketici elektroniğinden otomotive, tıbbi, ve havacılık endüstrileri, PCBA'lar modern teknolojinin temelini oluşturur. Tüketici elektroniğinde, akıllı telefonlar, dizüstü bilgisayarlar, ve akıllı ev cihazları yüksek düzeyde entegre PCBA'lara güveniyor. Otomotiv elektroniğinde, modern araç kontrol sistemleri, navigasyon, ve otonom sürüş özellikleri güvenilir PCBA'ya bağlıdır. Endüstriyel robotlar, otomasyon ekipmanları, ve hassas tıbbi aletler de stabil gerektirir, Doğru çalışmayı sağlamak için dayanıklı PCBA'lar.

Yapay zekanın hızlı gelişimiyle, 5iletişim, Ve Nesnelerin İnterneti (IoT), yüksek yoğunluklu talep, yüksek performanslı, ve çevre dostu PCBA'lar artıyor. Yapay zeka çipleri ve yüksek performanslı bilgi işlem gibi uygulamalar, PCB teknolojisini daha karmaşık devreleri ve daha yüksek hızlı sinyal iletimini yönetmeye zorluyor. Sonuç olarak, üreticiler modern elektroniğin gelişen gereksinimlerini karşılamak için yenilik yapmaya devam ediyor.

Çözüm:

Özetle, PCB temeldir, iskelet, PCBA bunun üzerine kuruluyken, geçim kaynağı haline gelmek, işlevsel “beyin”. Her ne kadar insanlar sıklıkla terimleri birbirinin yerine kullansa da, Elektronikle ilgilenen herkes PCB'nin devreleri olan çıplak bir kart olduğunu anlamalıdır, PCBA ise monte edilmiş bileşenlere sahip işlevsel bir karttır. Bir dahaki sefere o tanıdık yeşil devre kartını gördüğünüzde, Statik bir plandan dijital dünyamıza güç veren dinamik çekirdeğe kadar olan olağanüstü yolculuğunu takdir edeceksiniz..

Cevap vermek