SMT – Surface Mount Technology and THT – Through-Hole Technology Processes

Electronic assembly involves a wide range of techniques to place and attach electronic components onto printed circuit boards (PCBs). Among these techniques, Surface Mount Technology (SMT) and Through-Hole Technology (THT) are the most widely used.

Both methods have unique processes, advantages, and challenges, which make them suitable for different applications.

This document provides an in-depth professional analysis of SMT and THT processes.

1. Surface Mount Technology (SMT)

- Definition

SMT involves mounting electronic components directly onto the surface of a PCB. This

method eliminates the need for drilled holes, as components are attached to the board

using solder paste and secured during a reflow soldering process. SMT components,

commonly referred to as SMDs (Surface Mount Devices), are typically smaller and lighter

than their THT counterparts. - SMT Process Flow The SMT process is a highly automated and precise operation, consisting of the following key steps:

PCB Preparation

Cleaning: The PCB surface must be clean and free of contaminants to ensure proper adhesion of solder paste and components.

Stencil Application: A stencil is placed over the PCB to allow solder paste deposition only in areas where components will be mounted.

Solder Paste Application

Solder Paste Deposition: Solder paste is applied through the stencil onto the designated pads of the PCB using a squeegee. The paste consists of powdered solder alloy and flux to facilitate soldering.

Component Placement

Pick-and-Place Machines: Automated machines accurately place components onto the solder-pasted pads. The precision of placement is critical, especially for components with fine pitches.

Reflow Soldering

Preheat — Soak — Reflow — Cool

Inspection and Testing

Automated Optical Inspection (AOI): Ensures proper placement and soldering of components.

X-Ray Inspection: Used for components with hidden solder joints, such as Ball Grid Arrays (BGAs).

Functional Testing: Verifies the electrical performance of the assembled board.

- Advantages of SMT

Miniaturization: Allows for smaller, more compact designs.

High Automation: Enables high-speed, large-scale production with consistent quality.

Cost Efficiency: Reduces material usage and labor costs due to automation.

Enhanced Performance: Improved signal integrity due to shorter lead lengths and reduced parasitic effects.

- Challenges of SMT

Complexity: Requires advanced machinery and precise control.

Repair Difficulty: SMT components are harder to remove and replace compared to THT components.

Thermal Stress: Sensitive to heat during soldering, which may damage components.

- Applications of SMT

SMT is widely used in:Consumer electronics (smartphones, laptops, wearable devices)Automotive electronics (engine control units, infotainment systems)Telecommunications (routers, switches)Medical devices (portable diagnostic equipment)

2. Through-Hole Technology (THT)

- Definition

THT involves inserting electronic component leads through drilled holes in a PCB and soldering them to pads on the opposite side. This method provides strong mechanical bonds and is commonly used for components that require durability or handle high power. - THT Process Flow

The THT process, though less automated than SMT, follows these key steps:

- PCB Preparation

Drilling Holes: Holes are drilled at precise locations to match the leads of the components.

Plating: Holes are plated with conductive material to ensure proper electrical connectivity.

Component Insertion

Manual Insertion: For low-volume or prototyping work, components are inserted by hand.

Automated Insertion: For high-volume production, automated machines insert components into pre-drilled holes.

Soldering

Wave Soldering: The PCB passes over a wave of molten solder, which adheres to the component leads and pads.

Hand Soldering: Used for prototypes or small-batch production.

Inspection and Testing

Visual Inspection: Ensures proper solder joint formation and component alignment.

Functional Testing: Confirms the board operates as intended.

- Advantages of THT

Mechanical Strength: Leads pass through the PCB, creating robust connections suitable for mechanical stress.

High Power Handling: Ideal for components such as transformers, capacitors, and connectors.

Ease of Repair: Components are easier to replace or modify. - Challenges of THT

Lower Automation: Relies more on manual labor, increasing production time and cost.

Board Size: Requires more space due to the larger size of components and through-hole drilling.

Slower Production: Compared to SMT, THT is less efficient for high volume manufacturing. - Applications of THT

THT is commonly used in:

Industrial equipment (power supplies, heavy machinery)

Aerospace and defense electronics (reliable, rugged systems)

Automotive systems (high-power components)

Prototyping and small-batch production

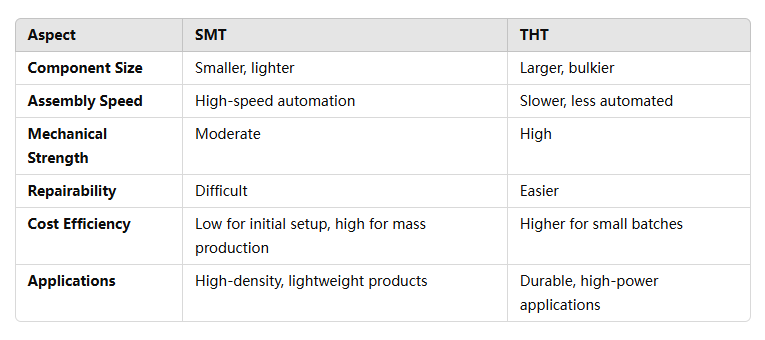

3. Comparison Between SMT and THT

4. Hybrid Assembly: Combining SMT and THT

In modern electronics, many designs use both SMT and THT technologies to leverage the strengths of each method.

For example:

- SMT is used for compact, high-speed components such as microcontrollers and ICs.

- THT is used for connectors, large capacitors, and other components requiring mechanical strength.

The hybrid assembly process involves:

- Completing the SMT assembly first.

- Running the partially assembled PCB through a THT process.

- Finalizing with inspections and functional testing.

5. Future Trends in SMT and THT

- Advances in SMT

Miniaturization: Development of smaller components and finer pitches.

3D SMT Technology: Enables placement on multiple PCB layers.

Improved Materials: Enhanced solder pastes and adhesives for better reliability. - Advances in THT

Selective Soldering: Reduces labor costs by automating THT soldering for specific areas.

Enhanced Durability: New plating techniques improve hole conductivity and mechanical

strength. - Industry Shifts

SMT is increasingly dominant in high-volume, high-density applications.

THT remains critical for niche markets requiring high power and reliability.

Conclusion

SMT and THT are essential technologies in PCB assembly, each catering to specific needs in the electronics industry.

SMT offers compact, high-speed assembly suitable for modern devices, while THT provides durability and power handling for specialized applications.

Understanding the processes, advantages, and limitations of both methods allows designers and manufacturers to create efficient, reliable, and cost-effective electronic products.