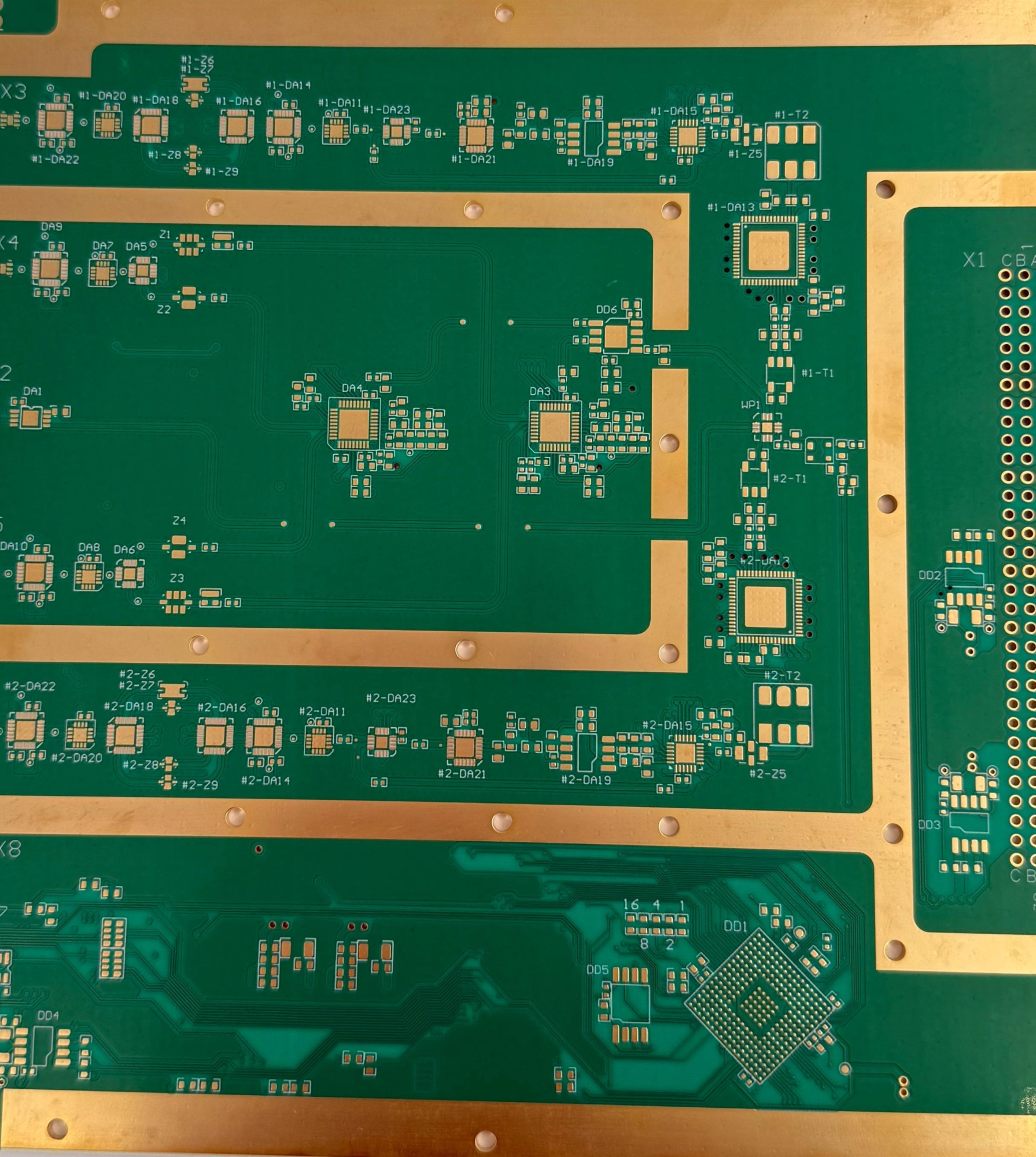

Rigid PCB — Durable, Reliable, Flame-Resistant

Rigid PCB is one of the three major types of Printed Circuit Boards (PCBs), alongside Flex PCBs and Rigid-Flex PCBs, classified by the substrate’s flexibility and application needs.

What is a Rigid PCB

Rigid PCBs are made from solid and inflexible materials such as:

🔹 Phenolic resin

🔹 Epoxy resin

🔹 Polyester glass

🔹 Most commonly: FR-4

FR-4 refers to a fire-retardant material composed of epoxy resin (as a binder) and electronic-grade fiberglass cloth (as reinforcement), laminated with copper foil.

PCB Layers Available

Rigid PCBs are available in multiple layer configurations:

-

Single-Layer PCB

-

Double-Layer PCB

-

Multi-Layer PCB — up to 40+ layers

Layer count depends on the complexity of the circuit design and the requirements of the end product.

Key Benefits of Rigid PCBs

✅ Excellent Dimensional Stability

Rigid PCBs maintain their shape and do not deform under pressure or heat over their lifecycle.

🔥 Flame Resistance

-

Most rigid PCBs have a temperature resistance of up to 130°C

-

High-performance boards can resist up to 170°C

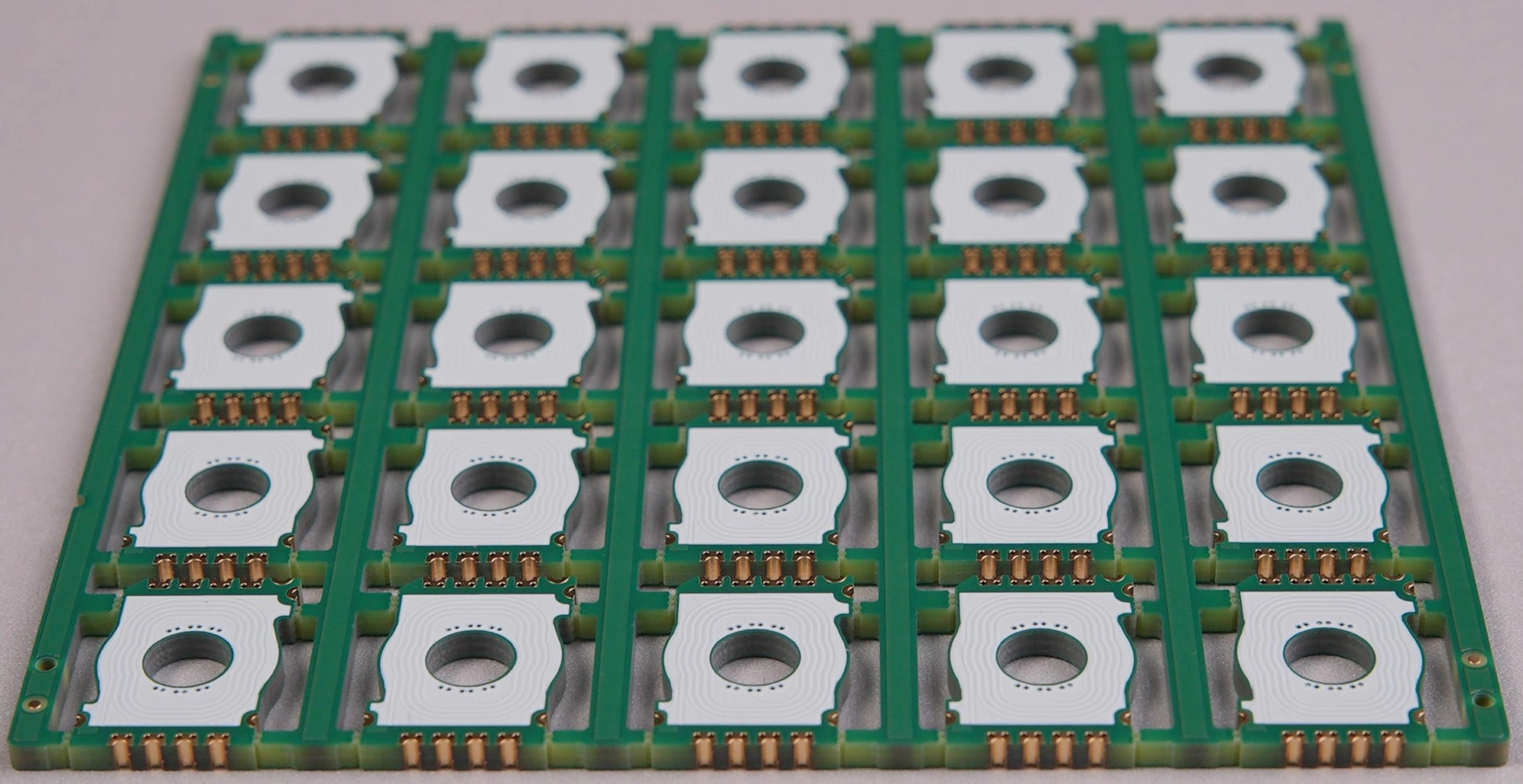

Applications of Rigid PCBs

Rigid PCBs are essential for durable electronics and core control systems. Common uses include:

-

Motherboards

-

Control boards

-

Button boards

-

Charger boards

-

Sensor boards

-

Consumer electronics

Summary

Rigid PCBs are the backbone of stable, high-performance electronic products. With:

-

Strong mechanical support

-

Flame retardant properties

-

Flexibility in layer design

-

Long product life cycles

They are ideal for high-precision and reliability-demanding applications.