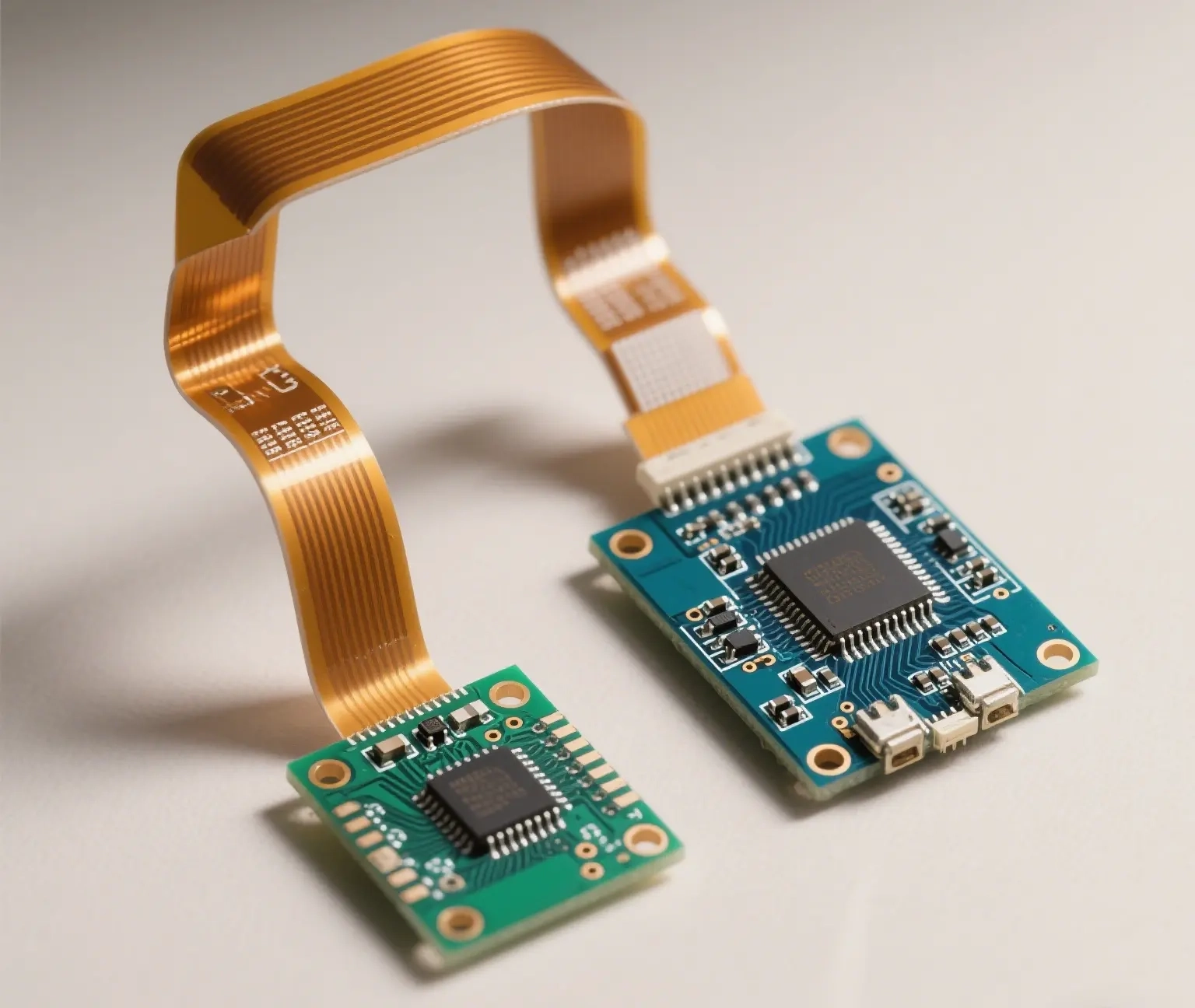

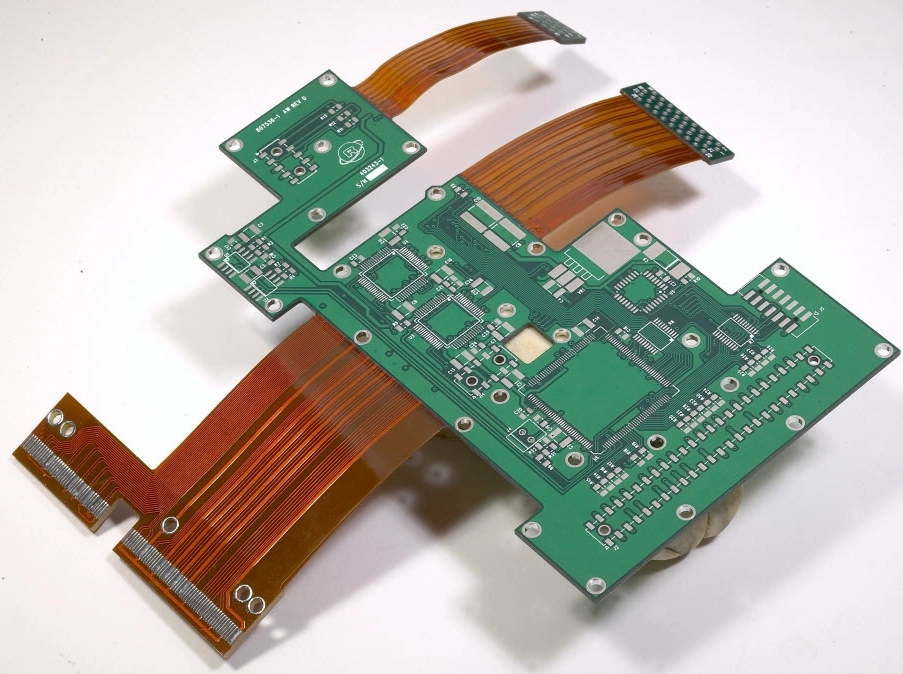

Rigid-Flex PCB — The Perfect Blend of Strength & Flexibility

Rigid-Flex PCB combines the benefits of both Rigid PCBs and Flexible PCBs, providing mechanical strength where needed and flexibility in areas that require motion or tight-space connections.

What is Rigid-Flex PCB

Rigid-Flex PCB is composed of two main parts:

-

Rigid PCB Section – Provides hardness, support, and stable component mounting

-

Flex PCB Section – Offers flexibility, bending ability, and compact connections

This hybrid structure is specially designed for:

-

Space-saving layouts

-

Complex internal interconnections

-

Simplified assembly

-

Enhanced product design efficiency

Materials Used

✅ Rigid Part: Typically made from FR-4

✅ Flex Part: Common materials include:

-

-

Polyimide (PI)

-

PEEK (Polyether Ether Ketone)

-

Conductive Polyester Films

-

Key Features of Rigid-Flex PCB

-

Compact & Flexible – Perfect for space-constrained or foldable designs

-

3D Design Freedom – Enables three-dimensional layouts

-

Superior Connectivity – High electrical reliability and minimal interconnect failure

-

Simplified Assembly & Testing – Fewer cables, connectors, and steps

Challenges to Consider

While offering many advantages, Rigid-Flex PCBs also come with increased complexity and cost in manufacturing.

Reasons include:

-

Precision layering and lamination processes

-

Longer production cycles

-

High-performance material requirements

Applications of Rigid-Flex PCB

Rigid-Flex PCBs are ideal for industries that demand compact size, reliability, and mechanical durability:

| Industry | Application |

|---|---|

| Aerospace | Flight control systems, sensors |

| Automotive | Camera modules, dashboard electronics |

| Consumer Electronics | Foldable phones, wearables |

| Medical Devices | Implants, diagnostic instruments |

| Telecommunications | Signal routers, handheld terminals |

Specific Examples

📱 Mobile phones

🎛️ Keyboards (press key boards)

💻 Computers and LCD screens

🖥️ Motherboards and display panels

🎵 CD Walkman and portable players