PCB VIA (Vertical Interconnect Access)

VIA, short for Vertical Interconnect Access, is a crucial element in multi-layer printed circuit boards (PCBs). These copper-plated holes allow electrical and thermal connections between layers, supporting compact, high-performance electronic devices.

What Is a VIA?

A via is a small hole drilled (mechanically or by laser) through PCB layers, filled or plated with copper, enabling electrical continuity between layers. It consists of:

-

Barrel: The conductive tube lining the hole.

-

Pad: The copper ring that connects the via to a trace.

-

Anti-pad: The clearance around the via to isolate it from non-connected copper layers.

🔧 How Are Vias Made

-

Copper pads are placed on each layer.

-

Holes are drilled through the stack at connection points.

-

The epoxy resin is removed chemically, exposing copper pads.

-

The barrel is formed by electroplating copper inside the hole.

-

Solder mask is applied to protect and isolate.

✔️ This process allows engineers to stack multiple layers efficiently, minimizing board size while maximizing circuit complexity.

🔍 Types of Vias

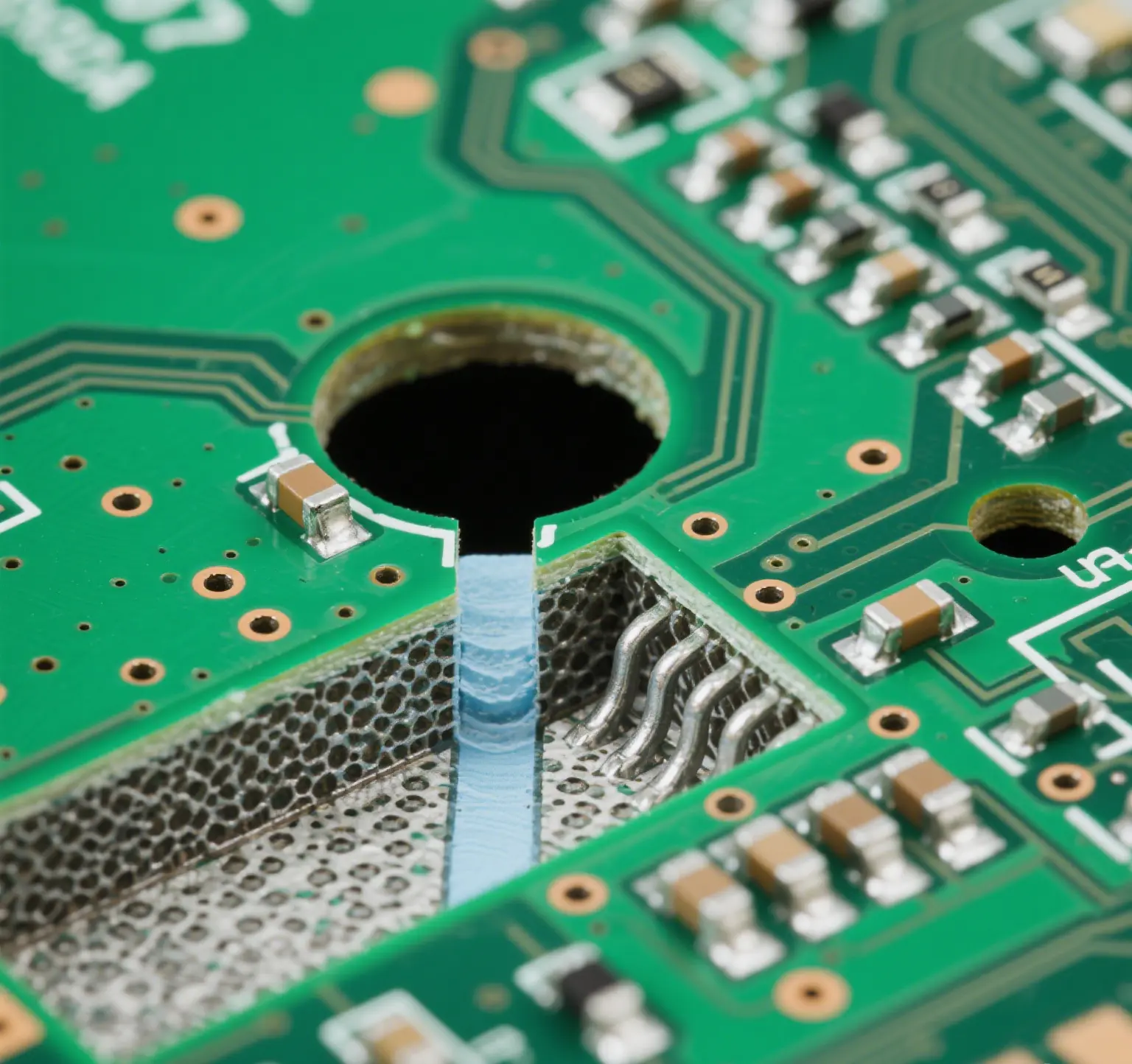

1️⃣ Through-Hole Vias

Fully penetrates the PCB from top to bottom.

Advantages:

-

Strong mechanical and electrical connection

-

Good thermal conductivity

-

Easy for inspection and rework

-

Supports through-hole components

Limitations:

-

Consumes space on all layers

-

Larger drill sizes limit layout density

-

May introduce signal reflections at high frequencies

Use Cases: Power/ground connections, connector mounting, thermal transfer.

2️⃣ Blind Vias

Connects outer layer to one or more inner layers, but doesn’t go through the entire board.

Benefits:

-

Increases routing density

-

Shorter electrical paths = better high-frequency performance

-

Saves board space

-

Reduces total layer count in complex designs

Applications:

Mobile devices, high-speed circuits, wearable electronics, aerospace systems.

3️⃣ Buried Vias

Completely enclosed inside the board—connects inner layers only, invisible from the outside.

Manufacturing Challenges:

-

Requires sequential lamination and drilling

-

Needs precise alignment

-

Harder to inspect (requires X-ray)

Advantages:

-

Excellent signal integrity

-

Lower EMI emissions

-

Frees up surface area

-

Greater routing flexibility

Applications: High-speed designs, RF boards, compact multilayer PCBs

Choosing the Right Via

| Via Type | Layer Connection | Cost | Space Saving | Signal Integrity |

|---|---|---|---|---|

| Through-hole | Full stack | Low | ❌ | Medium |

| Blind | Outer to inner | Medium | ✅ | High |

| Buried | Inner to inner only | High | ✅✅ | Very High |

| Micro via | Laser-drilled, small size | Very High | ✅✅✅ | Excellent |

Why Vias Matter in Modern PCBs

Vias support:

📡 Signal routing across layers

🔌 Power distribution and grounding

🌡️ Thermal management

🧩 High-density interconnects (HDI)

🎯 Precision performance in compact electronics

Summary

Vias are core elements in multi-layer PCB design. They impact everything from performance and size to manufacturing cost and signal integrity. Selecting the right via type is crucial for your product’s success in today’s fast-evolving electronics landscape.