PCB Materials Overview

Printed circuit boards (PCBs) use a variety of base materials depending on their performance, thermal, and electrical requirements. Below is a comprehensive overview of commonly used PCB materials.

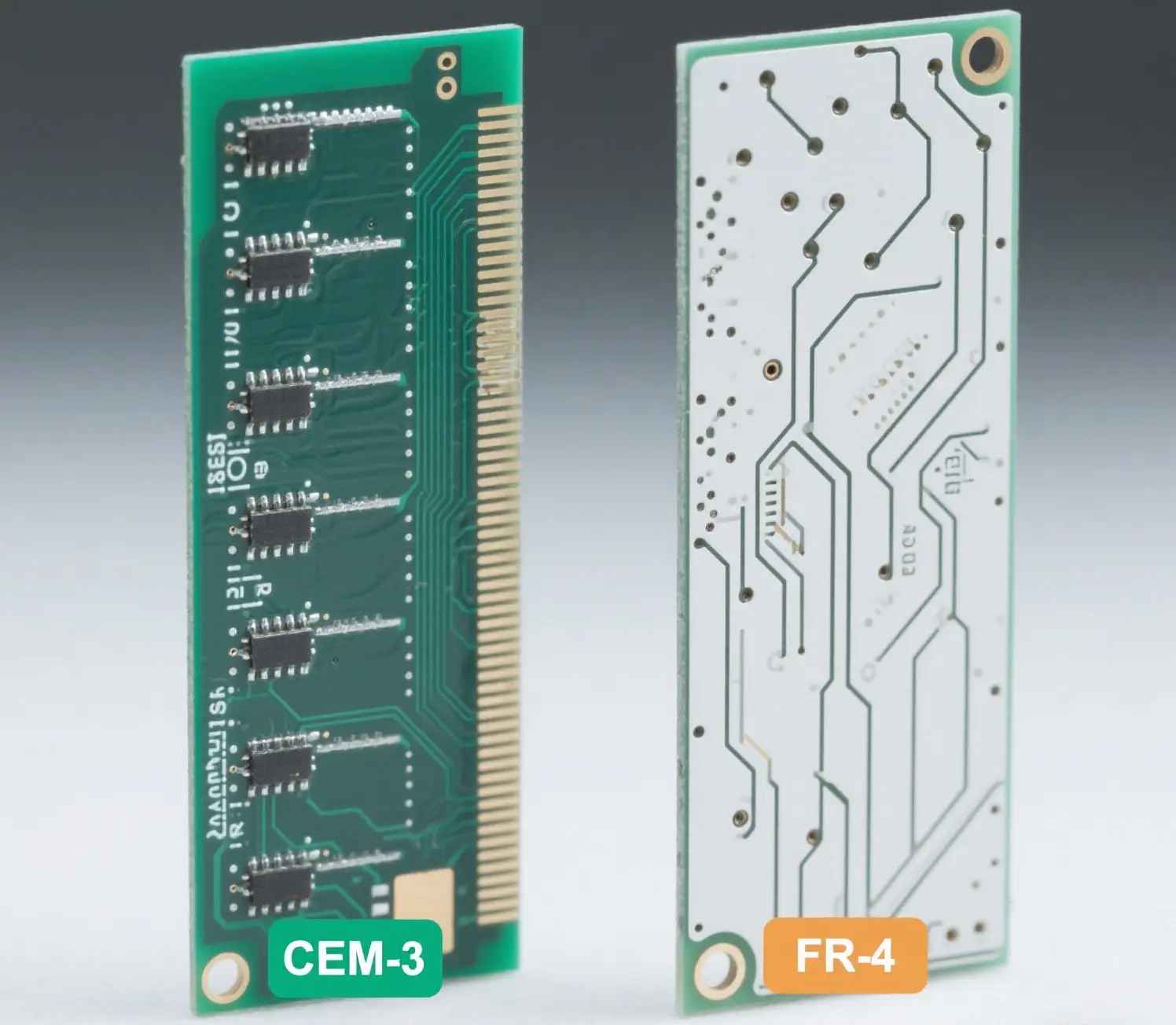

✅ FR-4 – The Standard Workhorse

Material: Woven fiberglass cloth + Epoxy resin

Applications: Over 90% of PCBs

Thickness: 0.2mm to 3mm

Key Features:

-

Affordable and reliable

-

Mechanically strong

-

Flame-retardant

✅ Grades of FR-4:

-

Standard FR-4 – For general multilayer boards

-

High Tg FR-4 – >170°C glass transition temp

-

Low loss FR-4 – Optimized for RF

-

High temp FR-4 – Up to 280°C solder resistance

-

Halogen-free – Eco-friendly, low smoke

-

High CTE – Reduced thermal stress

-

High flex – For dynamic bending

-

Low Dk – Enhanced signal performance

📶 Rogers – High-Frequency Performance

Material: Ceramic composite laminate

Applications: Aerospace, defense, telecom, medical

Advantages:

-

Low dielectric constant variation

-

Excellent signal integrity

-

Great thermal performance

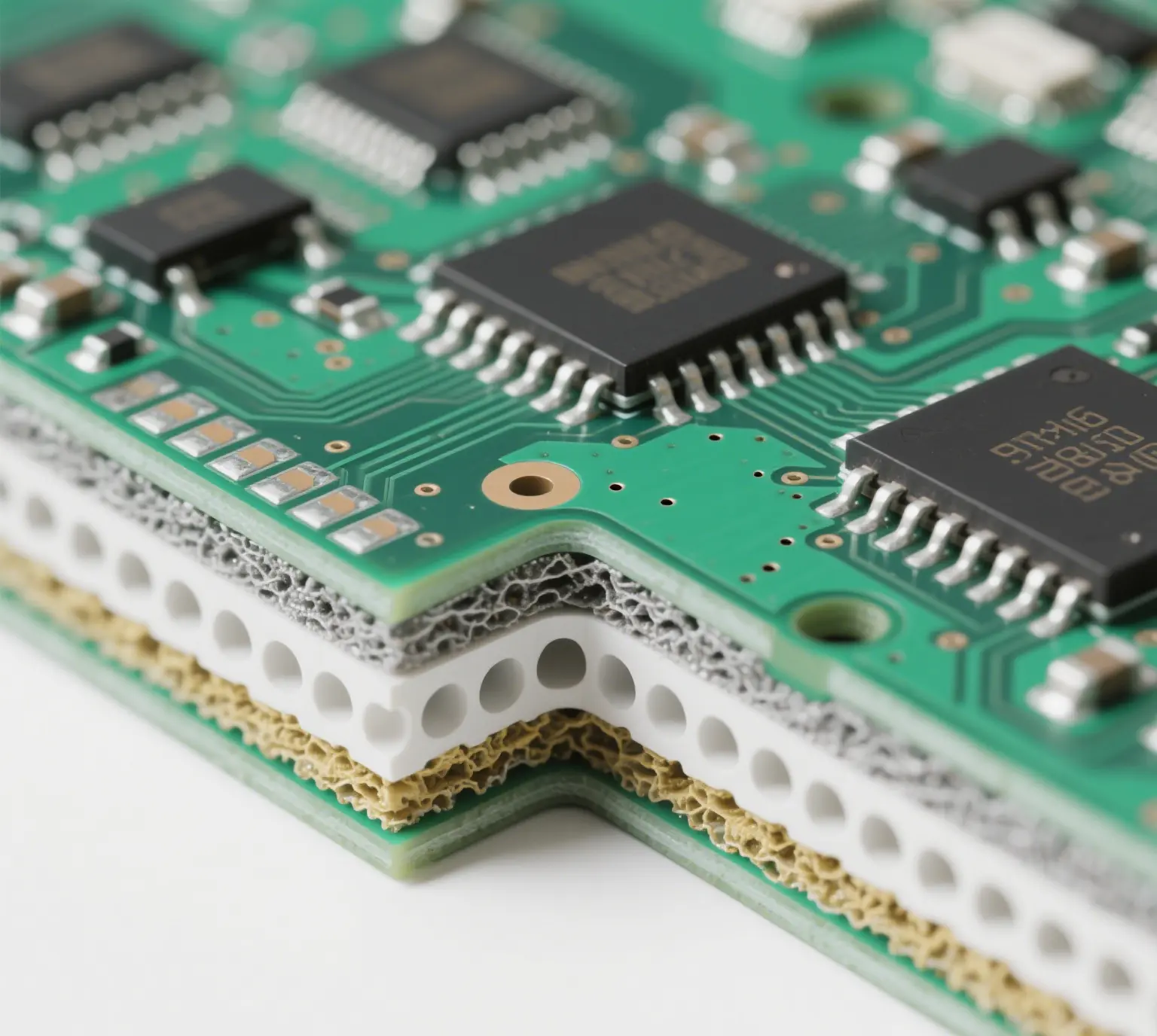

📈 Ceramic PCB – High Reliability

Materials: Alumina (Al₂O₃), AlN, BeO, LTCC

Key Benefits:

-

High temperature & frequency performance

-

Low thermal expansion

-

Excellent insulation

-

Low signal loss

Types We Offer:

-

Alumina PCB

-

Aluminum Nitride (AlN) Base

-

Copper Clad Ceramic

Thermal Conductivity Table:

| Material | Thermal Conductivity (W/mK) |

|---|---|

| Aluminum Nitride | 150 – 180 |

| Aluminum Oxide | 18 – 36 |

| Beryllium Oxide | 184 – 300 |

| Boron Nitride | 15 – 600 |

| Silicon Carbide | 70 – 210 |

Aluminum PCB – Heat Dissipation Champion

Advantages:

-

Lightweight, corrosion resistant

-

Excellent thermal conductivity

-

High mechanical strength

Applications: LEDs, power electronics, automotive, telecom

CEM-3 – Cost-Effective Alternative

Usage: High-end electronics (e.g. medical, automotive)

Pros:

-

Good mechanical & thermal stability

-

Lower cost than FR-4

Cons:

-

Higher dielectric constant

-

Lower chemical resistance

PI (Polyimide) – For Extreme Environments

Highlights:

-

Operates up to 400°C

-

Low dielectric loss

-

Excellent signal integrity

-

High thermal stress resistance

Applications: Semiconductor, aerospace, high-reliability electronics

Glass PCB – Optical Grade Precision

Usage: LED, LCD, high-precision optics

Advantages:

-

Thermal stability and homogeneity

-

UV mask etching process for precision

-

Supports fine pitch and narrow traces

Process Note:

Uses UV curable resist (positive/negative) for circuit patterning on copper-clad glass.

📌 Conclusion

Each PCB material type offers unique benefits tailored to specific applications. Choosing the right material ensures better performance, longevity, and reliability for your product.