PCB Assembly Services

From Prototype to Production – Precision Guaranteed

What is PCB Assembly?

PCB assembly is the process of populating a Printed Circuit Board (PCB) with all the required components. It includes:

-

DFA (Design for Assembly) analysis

-

Placement of surface-mount and through-hole components

-

Testing and final inspection

Attaching components to the PCB is the final step before using the fully operational electronic device.

What’s Needed for Efficient PCB Assembly?

To streamline your PCB assembly process, customers should provide:

-

A detailed Bill of Materials (BOM)

-

Assembly notes with:

-

Reference designators

-

Component orientation

-

Instructions for washable & non-washable parts

-

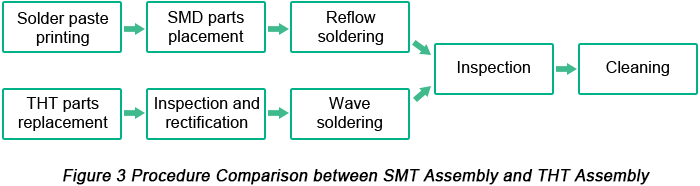

Methods of PCB Assembly

There are three main techniques used to create PCB assemblies. Each has its strengths based on the type of project.

1️⃣ Surface Mount Technology (SMT)

🔹 Components have conductive tabs that are soldered directly onto the PCB

🔹 Enables higher circuit density by placing components on both sides

🔹 Typically uses pick-and-place machines and reflow ovens

2️⃣ Through-Hole Technology (THT)

🔹 Components have leads inserted into pre-drilled holes

🔹 Assembled via wave soldering or manual soldering

🔹 Offers strong mechanical bonds, but higher cost and manual labor involved

3️⃣ Electro-Mechanical Assembly (Box Build)

Also known as box-build, this includes:

-

Wire harnesses & cable assemblies

-

Molded plastics

-

Metal enclosures

Used to combine the PCB with peripheral electronic hardware.

The Importance of Precision

Today’s electronics are rapidly evolving. With microelectronics gaining ground, precision in assembly determines the performance, durability, and efficiency of final products.

✅ A good PCB assembly = fewer reworks + faster time to market

Why Choose Fully Hong Electronics?

We’re your trusted partner for end-to-end PCB solutions, from fabrication to assembly and quality testing.

We offer:

-

Full or partial turn-key services

-

Access to a wide and reliable supply chain

-

Expertise in prototyping and mass production

-

In-house and partner-based quality assurance

Let our team handle complex procurement and component sourcing for you.

📦 COIN: Customer-Owned Inventory

COIN is our exclusive PCB component stocking program for premium clients.

🔹 Ensures hard-to-find parts are reserved for you

🔹 Minimizes supply risks

🔹 Enables smooth just-in-time assembly