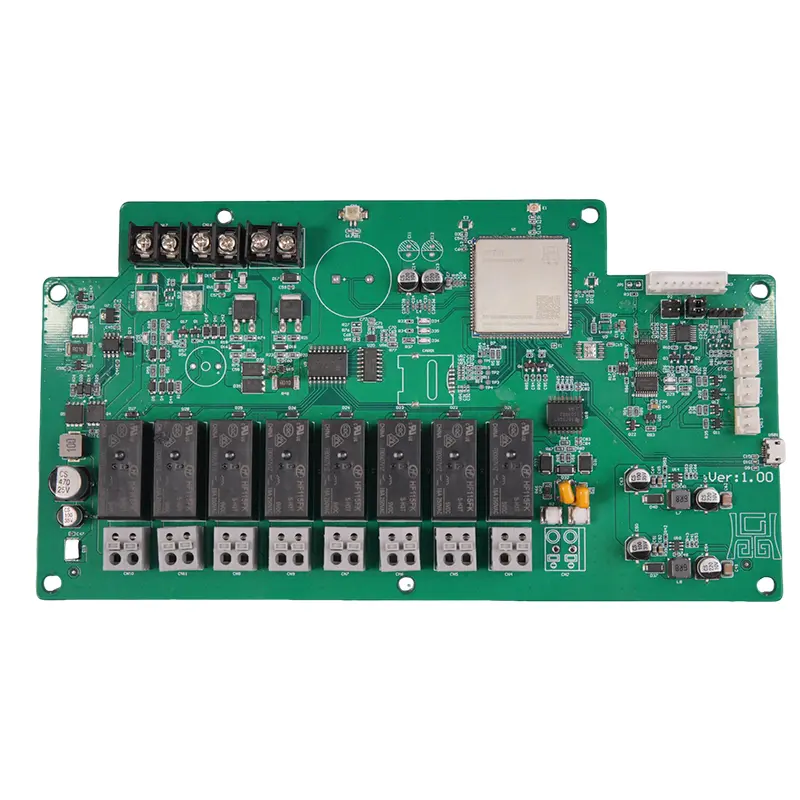

This 4-layer Tg150 PCBA is a tailored solution for power supply applications, combining advanced thermal management, high-efficiency energy conversion, and reliable performance. Engineered for industrial power supplies, server PSUs, and renewable energy inverters, the PCBA leverages a 4-layer FR4 PCB with a glass transition temperature (Tg) of 150°C to withstand moderate heat generated by power components, ensuring stable operation in environments up to 80°C. The inclusion of a customized transformer allows for precise voltage regulation and optimized power transfer, making it ideal for applications requiring high efficiency and low electromagnetic interference (EMI).

The 4-layer architecture separates power and signal domains to minimize cross-interference:

- Layer Stackup: 2 Couches de signalisation + 2 Alivins de puissance / sol, with 1OZ copper on all layers for balanced conductivity (up to 8A per wide trace) and EMI suppression.

- Tg150 FR4 Material: Offers better thermal stability than standard FR4 (Tg130°C), reducing the risk of delamination in power-dense areas like transformer and MOSFET zones.

- Thermal Vias: Strategically placed vias under power components enhance heat dissipation, lowering hotspot temperatures by 10-15°C compared to traditional 2-layer designs.

The integrated customized transformer is designed to meet specific power requirements:

- Tailored Specs: Configurable for voltage ratios (Par exemple, 1:1, 2:1), power ratings (50W-500W), and frequency ranges (50kHz-1MHz) to suit applications like AC-DC adapters or DC-DC converters.

- Efficiency Optimization: Low-core-loss materials (Par exemple, ferrite or nanocrystalline) and precise winding techniques ensure >90% energy transfer efficiency, critical for 80 PLUS-certified power supplies.

- EMI Suppression: Shielded windings and balanced magnetic design reduce radiated emissions, helping meet EN 55032/55022 EMI standards for industrial and consumer electronics.

The PCBA undergoes a streamlined, high-precision assembly process:

- Print Paste & Spice:

- Stencil printing of lead-free solder paste (SAC305) with ±5% volume accuracy, verified by 3D solder paste inspection (Spice) to prevent bridging in fine-pitch components (Par exemple, 0402 passives, SOICs).

- Pick & Place & Reflow:

- High-precision placement (±30μm) of SMT components, including power inductors, diodes, and control ICs, followed by nitrogen-assisted reflow soldering (peak 260°C) for void-free joints.

- AOI & Tht:

- Automated optical inspection (AOI) checks for misalignment or solder defects before through-hole technology (Tht) insertion of the customized transformer, connecteurs, and electrolytic capacitors.

- Wave Soldering & Hand Soldering:

- Lead-free wave soldering (250-260°C) ensures reliable THT joints, while manual soldering addresses delicate components or rework needs.

- Functional Testing & QA:

- FG Test: Load testing under full/half/no load conditions verifies voltage regulation (±1%), ripple noise (<100mV), and overcurrent protection (OCP) response time (<50ms).

- X-ray Inspection: Scans transformer solder joints and hidden vias for voids (<5%) or misalignment.

- Fai & Compliance: First Article Inspection (Fai) includes dimensional checks and material certification (RoHS/REACH), with IPC-A-610 Class 2 compliance ensured at every stage.

- Key Checkpoints:

- Spice: Ensures solder paste volume variation <10% to prevent open circuits in power paths.

- radiographie: Verifies transformer winding integrity and BGA joint quality in control ICs.

- Thermal Cycling: -40°C to +85°C, 500 cycles, to simulate real-world power supply stress.

- Standards Met:

- IEC 62368 (electrical safety), EN 61000 (EMC), and UL 60950 for information technology equipment.

- Industrial Power Supplies: 24V/48V DC supplies for factory automation, with active PFC and remote monitoring via the customized transformer’s feedback loop.

- Server & Data Center PSUs: High-efficiency (≥85%) power modules supporting 1U/2U servers, featuring the transformer’s low-profile design for space-constrained enclosures.

- Renewable Energy Inverters: DC-AC inverters for solar/wind systems, with the transformer enabling galvanic isolation and MPPT (Maximum Power Point Tracking) control.

- Électronique grand public: Fast-charging adapters (Par exemple, USB PD 3.0) with compact transformers for 65W+ output in laptops and gaming devices.

- Standard Lead Time: 4-5 semaines, including PCB fabrication, component sourcing, and testing.

- Expedited Service: 2-3 weeks available for urgent projects (subject to transformer customization complexity).

- Design Support: Collaborative design services to optimize transformer specs, mise en page, and thermal performance for unique power requirements.

By integrating a customized transformer with a robust 4-layer Tg150 PCBA, this solution delivers unmatched reliability and efficiency for power-critical applications. The combination of precision manufacturing, rigorous quality control, and flexible design makes it an ideal choice for engineers developing next-generation power supplies that balance performance, compliance, and cost-effectiveness. Whether used in industrial machinery, data centers, or consumer devices, this PCBA ensures stable power delivery and long-term operational integrity.