Introduction to Flexible Printed Circuits (FPC)

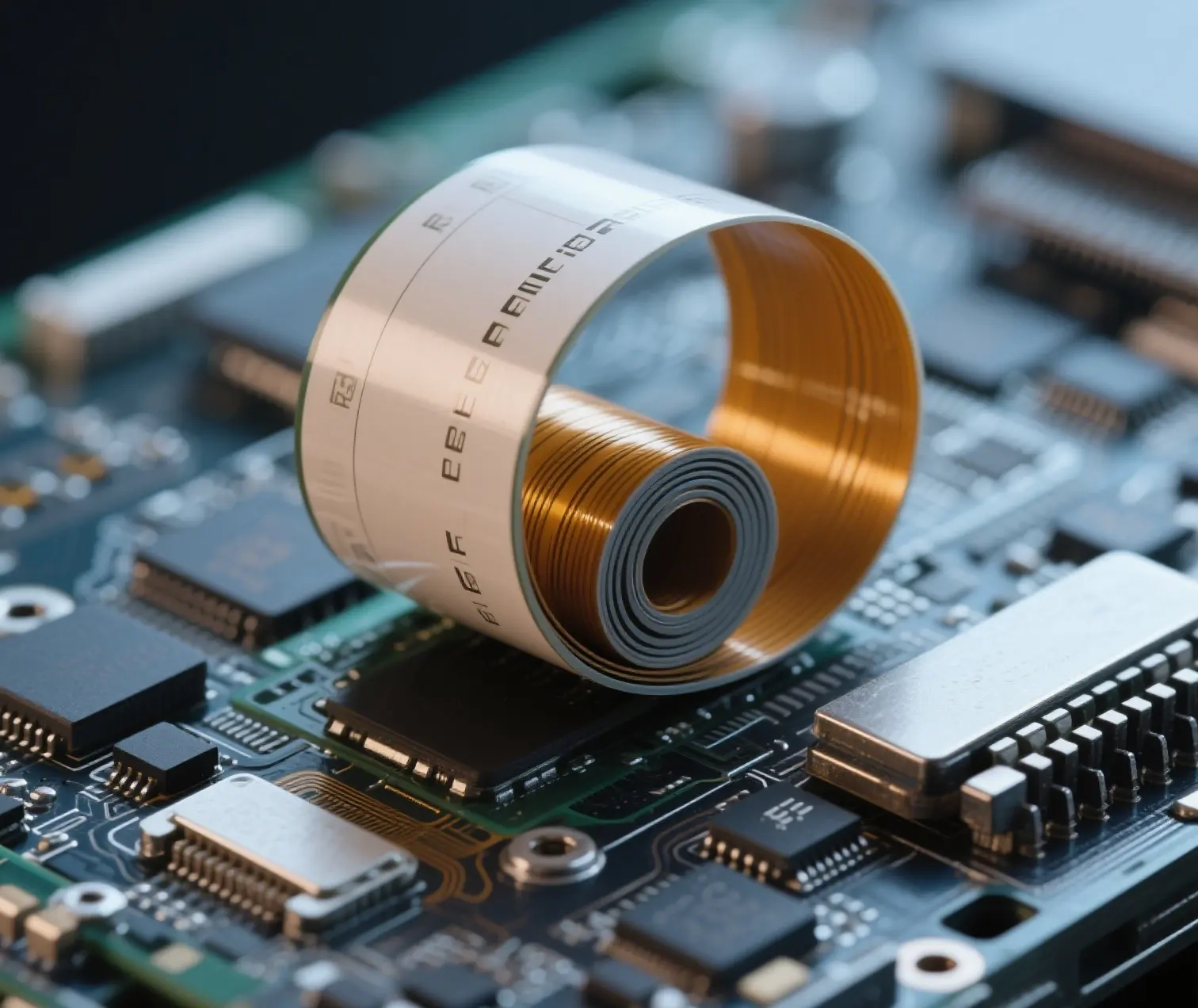

Flexible Printed Circuits (FPC) are at the heart of modern electronics — combining lightweight, space-saving, and adaptive features that redefine circuit design.

What is FPC

FPCs are flexible circuit boards that can bend, twist, and fold, making them ideal for compact and dynamic devices.

Key Attributes:

-

Flexibility for intricate designs

-

Lightweight and thin

-

Suitable for tight spaces and 3D arrangements

-

Durable under mechanical stress

FPC Production Process

FPC manufacturing involves precision engineering and multi-step fabrication. Here’s a typical workflow:

1️⃣ Substrate Preparation

Use of Polyimide or Polyester films

Copper foil laminated via adhesive or adhesiveless methods

2️⃣ Circuit Design & Photolithography

CAD software generates circuit

UV light exposure through photomask defines the pattern

3️⃣ Etching

Chemical solution removes unwanted copper

Clean-up leaves precise circuitry

4️⃣ Drilling & Plating

Micro-vias made via laser or mechanical drilling

Electroplating ensures conductivity

5️⃣ Coverlay Application

Polyimide coverlay shields from moisture/dust

Openings made for solder pads

6️⃣ Surface Finishing

Common finishes: ENIG, HASL, OSP

7️⃣ Assembly & Testing

Components soldered

Rigorous QC testing

Materials Used in FPC

| Component | Material | Characteristics |

|---|---|---|

| Substrate | Polyimide / Polyester | Thermal stability, flexibility |

| Conductor | Copper Foil | Excellent conductivity |

| Adhesives | Epoxy / Acrylic | Layer bonding |

| Protective Layer | Polyimide films / LPI | Circuit shielding |

| Surface Finish | ENIG, OSP, Silver | Solderability & durability |

Where FPCs Are Used

FPCs are widely applied in industries where reliability, miniaturization, and flexibility are key.

🔌 Consumer Electronics

-

Smartphones, tablets, wearables

-

Enables foldable screens & compact internals

🚘 Automotive

-

Used in sensors, dashboards, infotainment

-

Tolerant to vibration & heat

🏥 Medical Devices

-

Hearing aids, imaging tools, diagnostic equipment

🚀 Aerospace & Defense

-

Satellites, avionics, mission-critical systems

🤖 Industrial & Robotics

-

Confined space installations, motion applications

🌐 IoT & Wearables

-

Smartwatches, fitness bands, smart tags

Advantages of FPC

-

✅ Freely bendable & foldable – suitable for 3D wiring

-

✅ Compact & lightweight – perfect for miniaturized designs

-

✅ Good heat dissipation & solderability

-

✅ Reduced assembly complexity & overall cost

-

✅ Hard-Soft board hybrid designs can carry more components

Disadvantages of FPC

-

High initial cost – due to custom design and tooling

-

Difficult to modify/repair – requires access to base photomask

-

Size limitations – production equipment may limit board size

-

Fragility during handling – needs trained technicians for soldering/rework

Conclusion

Flexible Printed Circuits (FPC) are revolutionizing electronics, delivering unmatched adaptability and performance. Their widespread adoption across industries reflects their importance in the future of miniaturized, reliable electronic systems.

As the demand for smarter, smaller, and more durable electronics grows, FPCs will remain a key enabler of innovation.