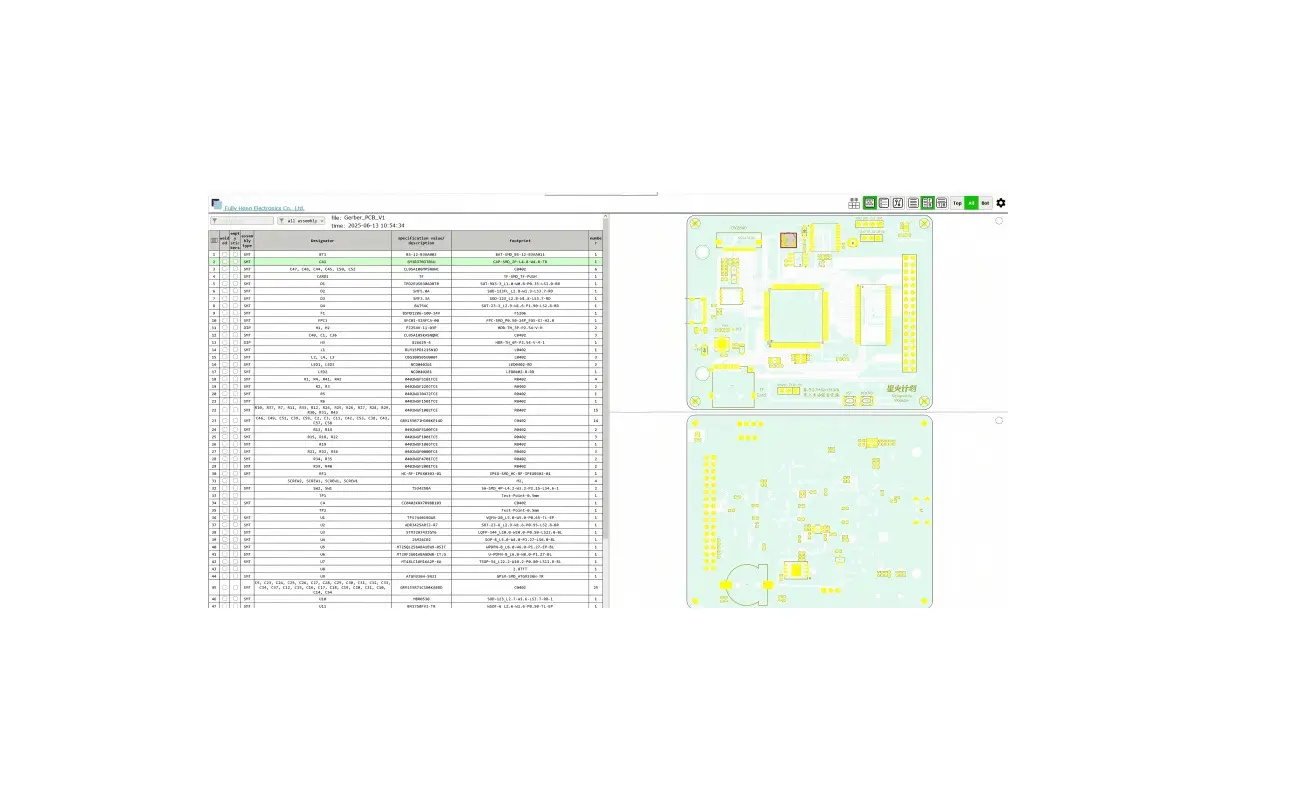

Im Bereich der Leiterplattenfertigung, Die technologische Weiterentwicklung hat die Branche schon immer zu höherer Effizienz und Präzision geführt. Als Dienstleister, der sich der hochwertigen Leiterplattenfertigung verschrieben hat, Wir halten stets an der Philosophie von fest “Technologie zuerst,” Wir integrieren modernste Open-Source-Technologien umfassend in unsere Produktionsprozesse und entwickeln gleichzeitig lokal Innovationen auf der Grundlage des Open-Source-Ökosystems. Unter diesen, das interaktive visuelle Stücklistensystem, das vom Open-Source-Projekt InteractiveHtmlBom aktualisiert wurde (Open-Source-Adresse: https://github.com/openscopeproject/InteractiveHtmlBom) hat einen entscheidenden Durchbruch bei der technischen Implementierung erzielt – es sind nur noch drei Kerndatendateien erforderlich: Gerber -Dateien, Stücklistenblätter, und Kartenkoordinatendateien – um eine vollständig interaktive visuelle Stückliste zu erstellen, Dadurch werden die Schwellenwerte für die Dateneingabe erheblich vereinfacht und die Effizienz der Zusammenarbeit in der Fertigung verbessert.

ICH. Technisches Upgrade: Leichte Dateneingabe rekonstruiert Herstellungsprozesse

Basierend auf dem Kern der Open-Source-Technologie, Unser technisches Team hat gezielte Optimierungen für PCB-Herstellungsszenarien durchgeführt, Der entscheidende Durchbruch liegt in der umfassenden Ausweitung der Datenkompatibilität:

- Leichtes Eingabesystem mit drei Dateien

- Gerber-Dateien: Lesen Sie physische Informationen wie Grafikebenen, Pads, und Siebdruck von PCB-Designs, um eine präzise Zuordnung der Komponentenpositionen zum Platinenlayout sicherzustellen.

- Stücklistenblätter: Unterstützt gängige Formate wie Excel/CSV, Parsen von Materialattributen wie Komponentenmodellen, Parameter, und Bezeichner.

- Kartenkoordinatendateien: Erfassen Sie Koordinaten- und Drehwinkeldaten von Komponenten auf der Leiterplatte, um eine millimetergenaue Positionierung für die Oberflächenmontage zu erreichen.

Durch unsere unabhängig entwickelte Datenparsing-Engine, Diese drei Dateien können verknüpft werden, ohne auf die Original-Designsoftware zurückgreifen zu müssen (wie KiCad, Adler), den Schmerzpunkt lösen “Design-Tool-Bindung” in traditionellen Lösungen, besonders geeignet für Fertigungsszenarien, die Kompatibilität mit Designdaten aus mehreren Quellen erfordern.

- Intelligenter Datenüberprüfungsmechanismus Neue automatische Vergleichsfunktionen wurden hinzugefügt:

- Überprüfen Sie die Konsistenz zwischen Stücklistenbezeichnungen und Gerber-Siebdruck, Markierungsanomalien wie doppelte Bezeichner oder fehlende Komponenten.

- Analysieren Sie den Grad der Übereinstimmung zwischen Kartenkoordinaten und Gerber-Pads, Bereitstellung von Frühwarnungen für Komponenten-Offset-Risiken, Kontrolle der Datenfehlerrate innerhalb 0.1%.

II. Technische Umsetzung: Innovation in Fertigungsszenarien mit Drei-Dateien-Eingabe

1. Vollständige Datenentkopplung für Multi-Source-Designkompatibilität

- Unabhängigkeit von Designtools: Ob Kunden Altium nutzen, LCDEDA, oder andere Werkzeuge, Durch einfaches Bereitstellen von Standard-Gerber+BOM+Map-Dateien kann eine visuelle Stückliste im einheitlichen Format generiert werden, Überwindung von Design-Software-Barrieren.

- Anpassungsfähigkeit an historische Projekte: Für überarbeitete Projekte ohne Original-Designdateien, Die visuelle Rekonstruktion kann ausschließlich mit archivierten Gerber-Daten aus der Produktion durchgeführt werden, Die technischen Hürden für die Sanierung alter Projekte werden erheblich gesenkt.

2. Steigerung der SMT-Fertigungseffizienz: Beschleunigung von “Datenvorbereitung” Zu “Produktionsausführung”

- Verbesserte Effizienz der Datenverarbeitung: Herkömmliche Lösungen stützten sich auf Designsoftware, um bestimmte Formatdateien zu exportieren, ungefähr nehmen 2-4 Std.; Der aktuelle Drei-Dateien-Eingabemodus ermöglicht ein schnelles Parsen innerhalb 15 Minuten, Besonders geeignet für den schnellen Wechsel von Klein- und Mehrserienaufträgen.

- Optimierung der Anpassung der Produktionslinie: Die generierte visuelle Stückliste ist gleichzeitig mit dem Koordinatenimport für AOI-Geräte der Produktionslinie kompatibel. Bediener können Komponentenpositionen direkt über die visuelle Schnittstelle abrufen, Zusammenarbeit mit intelligenten Bestückungsmaschinen, um dies zu erreichen “Eingabe und Ort” Funktionalität.

3. Upgrade der Kundenzusammenarbeit: Lightweight Delivery reduziert die Kommunikationskosten

- Standardisierte Leistungen: Stellen Sie Ihren Kunden integrierte HTML-Dateien mit visuellen Gerber-Vorschauen zur Verfügung, Stücklistentabellen, und Komponentenkoordinaten, ohne Installation von Software sichtbar, voll kompatibel mit Mobiltelefonen und Computern.

- Self-Service-Problemort: Kunden können auf Komponentengrafiken in der HTML-Oberfläche klicken, um entsprechende Stücklistenparameter und Kartenkoordinaten in Echtzeit anzuzeigen, selbständig abschließen “Design-Herstellung” Datenüberprüfung und -reduzierung 80% von manuellen Kommunikationsanfragen.

III. Hauptvorteile, wenn Sie sich für uns entscheiden: Wertsprung im verarbeitenden Gewerbe durch technische Verbesserungen

- Datenkompatibilität: Überwindung von Design-Tool-Barrieren Im Vergleich zur ursprünglichen Open-Source-Lösung, die auf spezifische Design-Software angewiesen war, Unser Drei-Dateien-Eingabemodus erreicht 99% Kompatibilität mit PCB-Designdaten. Ob einfache Designs von Start-ups oder Dateien in Industriequalität für komplexe Mehrschichtplatinen, Sie können schnell in visuelle Stücklisten umgewandelt werden, Beseitigung von Produktionsverzögerungen, die durch verursacht werden “Inkompatibilität des Designtools.”

- Effizienzrevolution: Vollständige Beschleunigung von der Datenaufbereitung bis zur Produktion

- Datenverarbeitungszeit komprimiert von 2-4 Stunden bis innerhalb 15 Minuten, Verkürzung der Projektstartzyklen um 70%.

- Nacharbeitsraten aufgrund von Datenfehlern im SMT-Prozess reduziert um 95%, mit Bestückungserträgen für Mikrobauteile wie 0201 verbessert 99.98%.

- Kostenoptimierung: Leichtbautechnologie reduziert die Zusammenarbeitskosten für beide Parteien

- Kunden müssen keine Design-Softwarelizenzen erwerben oder komplexe Exportprozesse erlernen, Es müssen lediglich grundlegende Produktionsdateien bereitgestellt werden, um die Zusammenarbeit abzuschließen.

- Wir reduzieren den Aufwand für die manuelle Datenverarbeitung durch technische Verbesserungen, Dies spiegelt direkt Kosteneinsparungen bei der Servicepreisgestaltung wider, mit reduzierbaren Preisen um 15%-20% für die gleichen Leistungen.

Sofortige Erfahrung: Kostenloser visueller Stücklisten-Produktionsservice jetzt geöffnet!

Wenn Sie die Effizienz und den Komfort der visuellen Stücklisteneingabe mit drei Dateien aus erster Hand erleben möchten, Bitte senden Sie Ihre Gerber-Dateien, Stücklistenblätter, und Ordnen Sie Koordinatendateien unserer E-Mail zu: [Geben Sie hier Ihre E-Mail-Adresse ein]. Wir erstellen für Sie kostenlos eine visuelle Stückliste, ohne Gebühren oder zusätzliche Bedingungen! Warte einfach, und Sie erhalten eine HTML-Datei mit interaktiver Bauteilpositionierung und präziser Stückliste, Intuitiv den Komfort spüren, den die Technologie mit sich bringt.

Gleichzeitig, um Ihnen zu helfen, die Vorgänge und Funktionen der visuellen Stückliste besser zu verstehen, Wir haben sorgfältig ein detailliertes Demonstrationsvideo aufgenommen. Sie können es im Videobereich unten ansehen:

Wenn Sie Fragen zur Vorbereitung von Dateien oder andere Anforderungen bezüglich der visuellen Stückliste haben, Bitte zögern Sie nicht, uns per E-Mail oder über den Kundendienst zu kontaktieren. Wir freuen uns darauf, Ihre Leiterplattenfertigungsprojekte mit technischer Stärke zu begleiten und gemeinsam eine neue Ära der effizienten und präzisen Zusammenarbeit einzuleiten!

Hinterlasse eine Antwort