In today’s fast-paced world of electronics, nearly every innovation — from smart wearables to aerospace systems — relies on one essential foundation: the printed circuit board (PCB). But behind this seemingly simple green board lies a highly sophisticated and globalized industrial ecosystem. Have you ever wondered how your product idea can efficiently travel from concept to mass production with reliability and speed?

Understanding the structure, evolution, and dynamics of the global PCB supply chain allows companies to better plan their projects, optimize supply chains, Und, most importantly, choose a trustworthy manufacturing partner. In diesem Artikel, we’ll explore the evolution of the PCB industry, analyze the global collaboration model, uncover future trends, and highlight how Voll Hong serves as your strategic partner to drive innovation with seamless, full-stack PCB/PCBA services.

1. From Hand Wiring to Smart Manufacturing: The Evolution of the PCB Industry

PCBs (Printed Circuit Boards) reflect the progression of the entire electronics industry. Originally, components were manually wired — a slow and unreliable process. In the 1940s, printed circuit technology emerged, ushering in the era of single-sided PCBs, which improved production efficiency and product consistency.

By the second half of the 20th century, demand for higher functionality and miniaturization gave rise to multilayer boards, HDI (High-Density Interconnect), flex PCBs, and rigid-flex PCBs — critical for applications like smartphones and wearables. As globalization accelerated, manufacturing shifted to Asia, shaping today’s complex and segmented global PCB supply chain.

2. Anatomy of the Global PCB Supply Chain

The PCB ecosystem involves multiple stages and specialized participants:

✔ Design & Pre-Engineering

-

Schematic Design: Engineers draft circuit diagrams based on product functions.

-

PCB -Layout -Design: Using EDA tools, designers convert schematics into physical layouts. Design für die Herstellung (DFM) is critical at this stage.

✔ Base Materials & Raw Supply

Includes copper-clad laminates (FR4, high-frequency, or flexible substrates), copper foils, solder masks, and plating chemicals — the quality of which directly impacts final product reliability.

✔ PCB Fabrication

-

Imaging & Radierung: Create circuit patterns by removing excess copper.

-

Bohren & Überzug: Ensure electrical connectivity through vias.

-

Lamination: Combine multiple layers under heat and pressure.

-

Lötmaske & Seidenbildschirm: Protect circuits and print component labels.

-

Oberflächenbeschaffung: Apply gold, OSP, or HASL for reliable solderability.

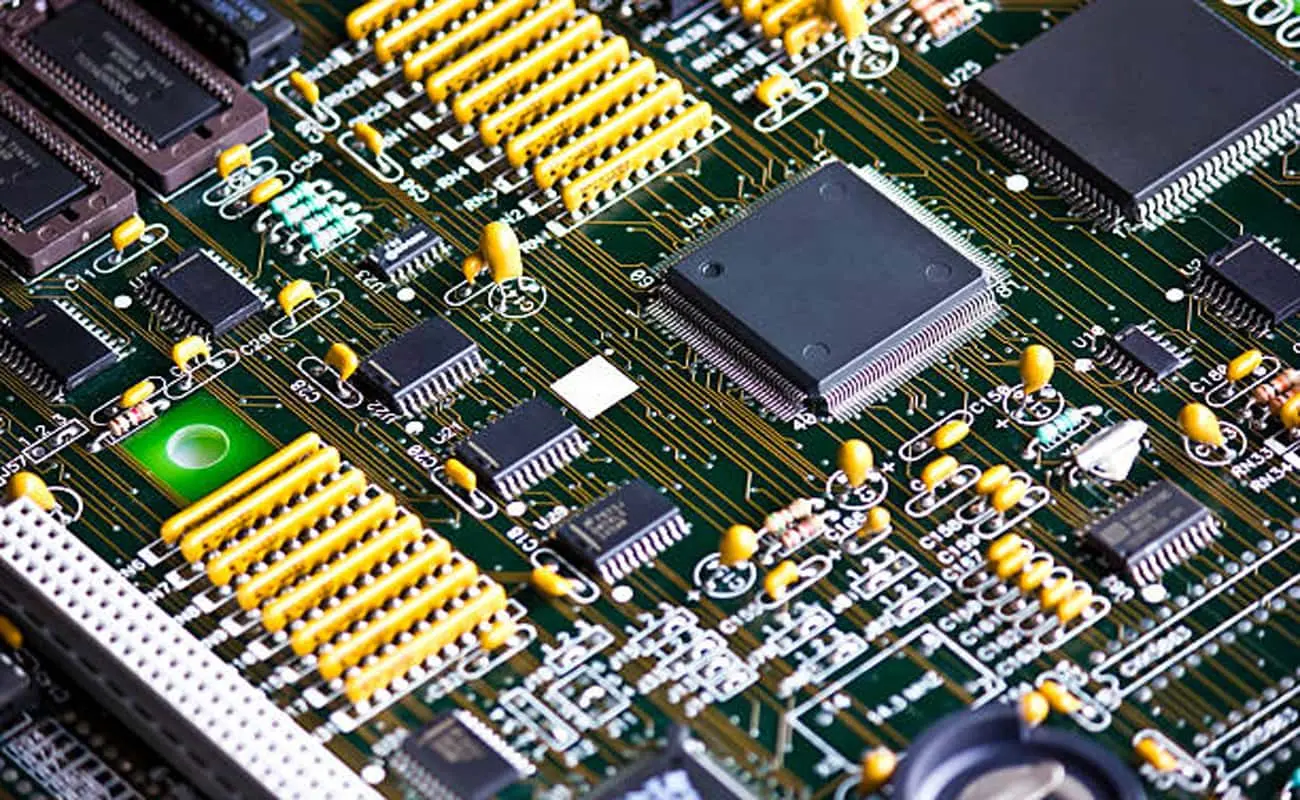

✔ Component Sourcing

Procuring genuine, high-quality components (ICs, Anschlüsse, Kondensatoren) from global suppliers is critical to avoid delays or defects — especially during shortages.

✔ PCBA Assembly

-

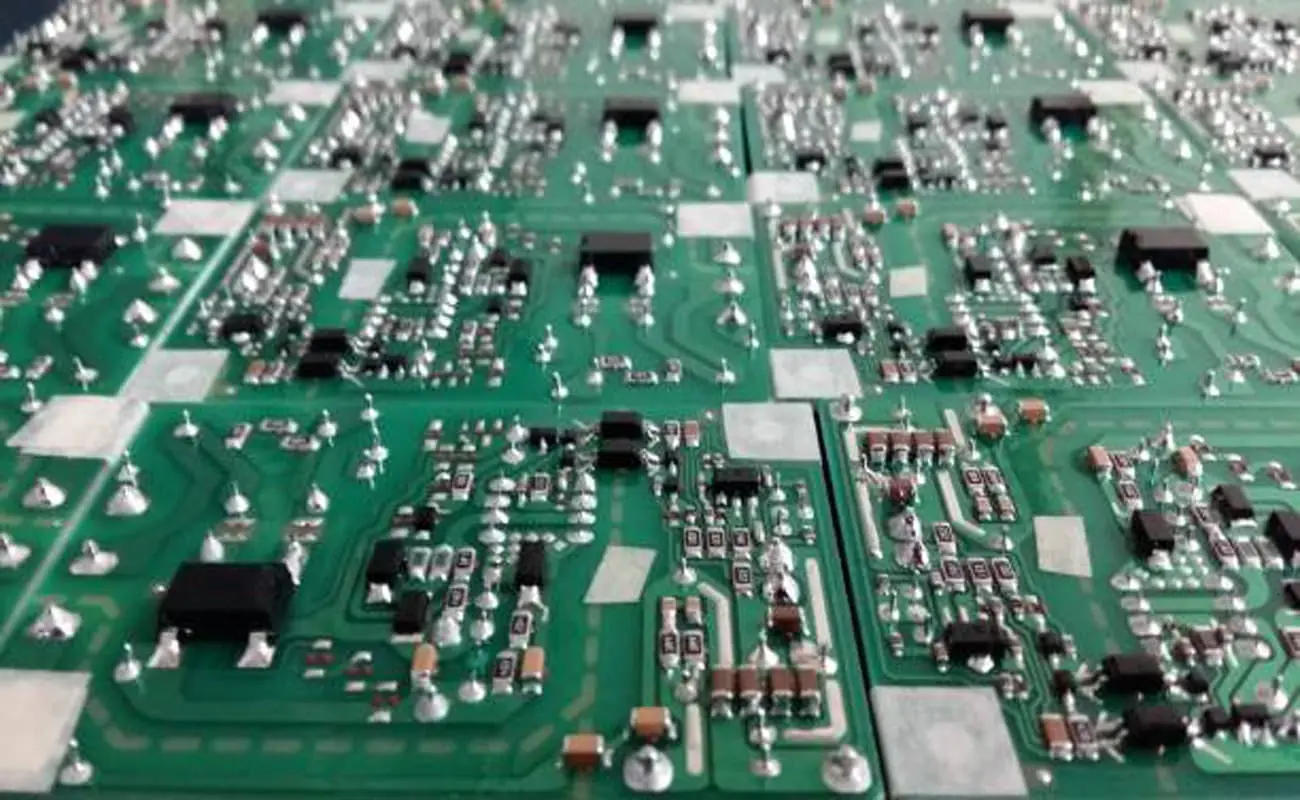

SMT (Oberflächenmontage -Technologie): High-speed placement of components followed by reflow soldering.

-

Wave/Selective Soldering: For through-hole components.

-

Manual Soldering: For custom or small-batch requirements.

✔ Testing & Inspection

-

Aoi (Automatisierte optische Inspektion)

-

X-Ray Inspection for hidden solder joints (BGA/QFN)

-

IKT (In-Circuit-Tests)

-

FCT (Funktionstests)

-

Aging Test under extreme conditions to ensure reliability.

3. Evolving Collaboration Models & Industry Challenges

As complexity grows, so does the need for specialization.

✦ Common Models:

-

EMS (Elektronikherstellungsdienstleistungen): Brands outsource production.

-

ODM (Original Design Manufacturer): Provides both design and manufacturing.

-

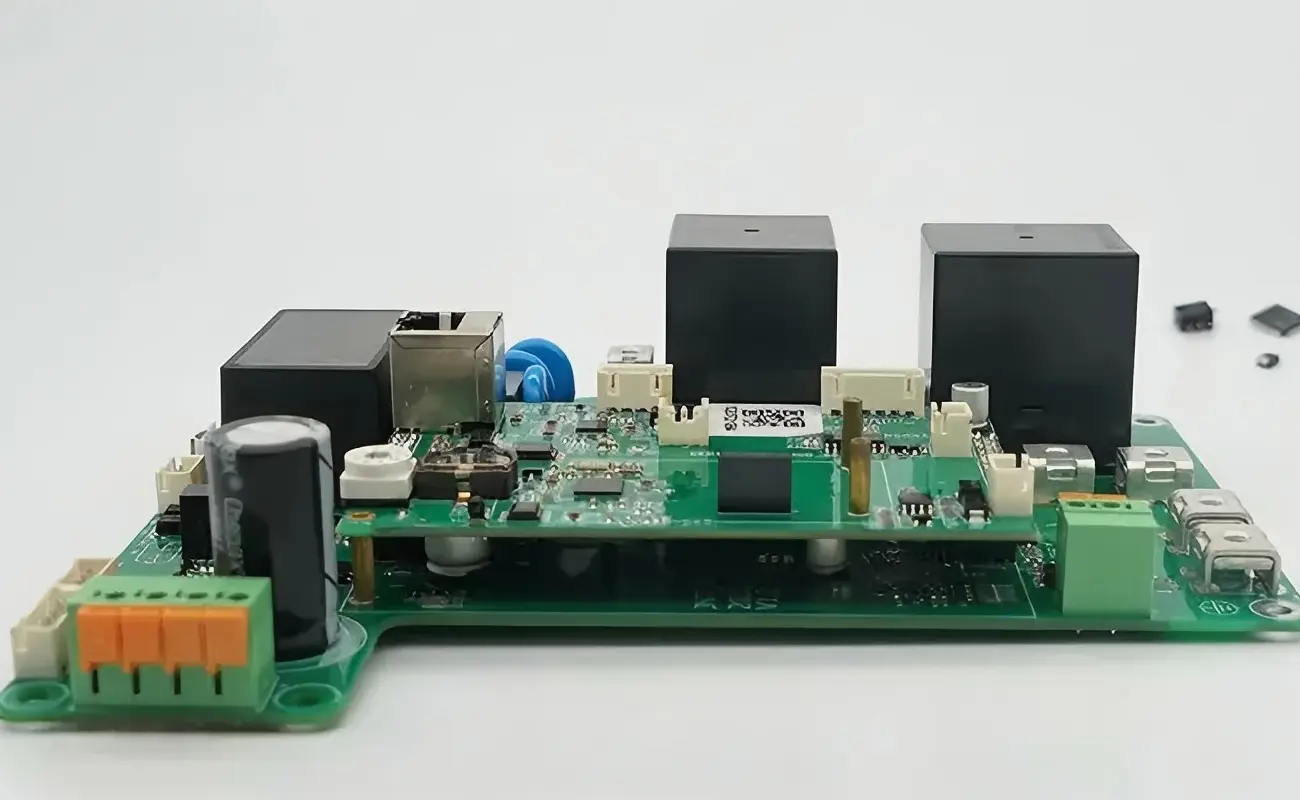

Turnkey One-Stop Services: Companies like Fully Hong handle everything from DFM, raw materials, Montage, Testen, to global logistics — simplifying management and reducing time to market.

✦ Ongoing Challenges:

-

Supply Chain Resilience: Geopolitical tensions, chip shortages, and pandemic disruptions require adaptable planning.

-

Quality Traceability: Managing quality across multi-country supply networks is increasingly complex.

-

Speed & Customization: Rapid iteration and small-batch production demand flexible systems.

-

Umweltkonformität: Sustainability is now a competitive advantage, not just a regulatory requirement.

4. What Drives Future PCB Development?

Technology Acceleration:

-

Miniaturization & Integration: HDI, SLP, and Embedded Components.

-

New Materials: For 5G, AI, EVs — low-loss, high-frequency substrates.

-

Function-Integrated Modules: SiP (System-in-Package) is blurring lines between PCB and semiconductor.

Market Expansion:

-

5G & Telekommunikation: Fueling demand for high-speed PCBs.

-

AIoT & Unterhaltungselektronik: Requires low-power, high-reliability PCBA.

-

EVs & Automotive Systems: High-temperature and high-voltage PCBs.

-

Medizinische Elektronik: Micro PCBs for wearable diagnostics and implants.

Smart Manufacturing & Sustainability:

-

Industrie 4.0 Integration: Automation, predictive maintenance, and real-time analytics will drive efficiency.

-

Green Production: Lead-free, halogen-free materials, energy-efficient processes, and closed-loop recycling.

Warum vollständig Hong wählen?

In a world of complexity and competition, Fully Hong is your one-stop partner for innovation, agility, and quality.

✅ Turnkey Services: From PCB layout, fabrication, global sourcing to precision PCBA and delivery — eliminate multi-vendor coordination.

✅ Global Sourcing Strength: We manage shortages, suggest reliable substitutes, and ensure stable supply with strategic reserves.

✅ Engineering & Quality Excellence: High-mix, high-density, or HDI — our expert team and world-class facilities ensure top-tier performance.

✅ Custom Solutions & Speed: Whether prototyping or scaling, we adapt to your needs with rapid response and personalized support.

📌 Let’s build the future, together. Don’t let fragmented supply chains slow you down. Partner with Voll Hong and turn your ideas into reality.

🌐 Website: https://www.pcb-leader.com

📞 Mobile: +86 13798350430

📲 WeChat/WhatsApp: +86 13798350430 / +86 17722543446

📧 Email: info@uly-hong.com

📠 Tel/Fax: +86-755-2664 8236

Hinterlasse eine Antwort