Die Teilnahme an Elektronikmessen im Ausland ist eine wichtige Werbestrategie für Voll Hong Elektronikunternehmen Ltd., Unterstützung bei der Entwicklung von Kunden, Kommunikation verbessern, und Vertrauen aufbauen. Unser Unternehmen nimmt in der Regel jedes Jahr an drei bis fünf internationalen Elektronikmessen teil, in der Regel mit einem 9 Quadratmeter großen Standardstand. Größer, Gut finanzierte Unternehmen wie börsennotierte Unternehmen verfügen möglicherweise über größere Stände mit besonderer Dekoration. Die Standgröße und die Ausstellungsformate variieren, Eines bleibt konstant: Hervorhebung der Unternehmensdifferenzierung, um potenzielle Kunden anzulocken, Interagieren Sie mit mehr Besuchern, effektive Kontakte sammeln, und zukünftige Geschäftsmöglichkeiten sichern. Dies zu erreichen ist eine Herausforderung. In diesem Artikel, Wir konzentrieren uns auf den Aspekt der Plakatgestaltung unserer Ausstellungsdisplays, erklären, wie wir wichtige Informationen vermitteln, und hoffen auf konstruktives Feedback zur weiteren Verbesserung.

Poster 1 – Über das Unternehmen

Das erste Poster zeigt das Logo unserer Muttergesellschaft, Vollständig Hongelektronik, zusammen mit unserer Website und unserem Slogan, die Besuchern helfen sollen, unseren Geschäftsumfang schnell zu verstehen. Zu den Texthervorhebungen gehören:

-

Fabrikgröße: 10,800 Quadratmeter

-

Produktionslinien: 9 SMT-Linien, 12 Montagelinien

-

Mitarbeiter: Über 300 Personal

Auch in Sachen Qualität betonen wir unsere Vorteile, Effizienz, und Kosten, und enthalten Bilder unserer SMT-Produktionslinien und PCBA-Produkte. Dieses Poster vermittelt, dass wir ein kompetenter und zuverlässiger PCBA-Hersteller sind.

Poster 2 – Produktübersicht

Das zweite Poster nutzt vor allem Bilder zur Darstellung unserer Hauptleistungen:

-

PCB -Herstellung

-

PCBA -Baugruppe

-

Komponentenbeschaffung

Dieses Poster vermittelt den Messebesuchern schnell unser Kerngeschäft.

Poster 3 – Produktionsprozess

Das dritte Poster erläutert den gesamten PCBA-Produktionsablauf, Dies ist für Besucher, die mit PCBA noch nicht vertraut sind, oder für neue Vertriebsmitarbeiter von großem Nutzen.

-

Oberer Abschnitt: Überblick über den PCBA-Produktionsprozess

-

Mittelteil: Dienstleistungen und Lieferzeiten – typischerweise, PCBA-Angebote dauern 2–3 Tage; Die Beschaffung von Komponenten erfordert im Allgemeinen 2 Wochen; Die Standard-PCBA-Verarbeitung dauert 3–7 Tage.

-

Unterer Abschnitt: Kontaktdaten des Unternehmens

Dieses Poster befasst sich hauptsächlich mit Bedenken hinsichtlich der PCBA-Vorlaufzeit.

Poster 4 – Supply-Chain-Management-Strategie

Das vierte Poster beleuchtet unsere Supply-Chain-Management-Strategie, Wir betonen, dass wir nur brandneue Produkte beziehen, authentische Komponenten. Shenzhen ist ein globales Zentrum für Hardware R&D und Fertigung, Die Qualität der Komponentenlieferanten ist jedoch sehr unterschiedlich. Viele Kunden befürchten, dass Fabriken generalüberholte oder minderwertige Komponenten verwenden. Fully Hong hält sich strikt an die Beschaffung von Originalteilen, diese Bedenken auszuräumen.

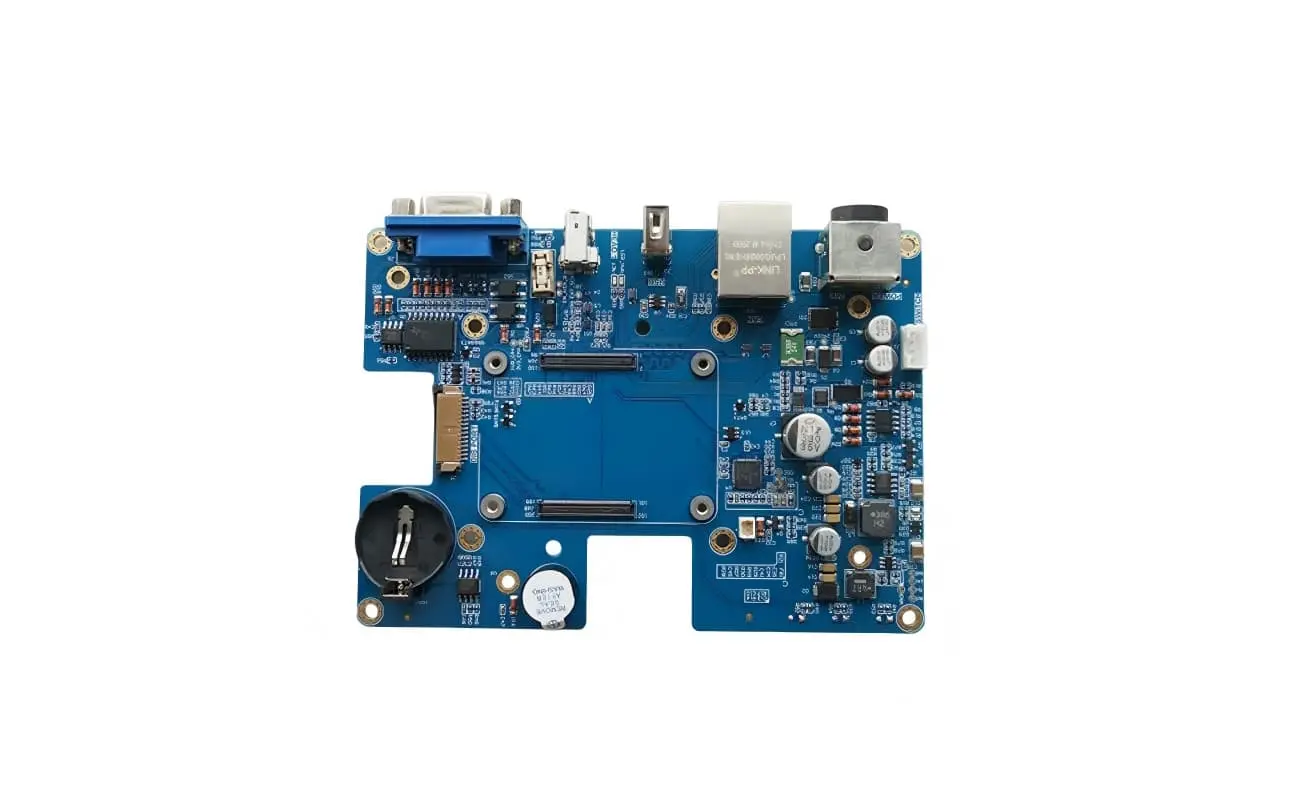

Poster 5 & 6 – Leiterplatte & PCBA-Produkte

Diese beiden Poster stellen lediglich einige unserer PCB- und PCBA-Produkte vor. Aus Platzgründen, Wir gehen nicht detailliert auf bestimmte Projekte ein. Rückblick, Diese Poster könnten durch die Hervorhebung anspruchsvoller Projekte in den Bereichen Industriekontrolle oder Medizin verbessert werden, um unser Fachwissen besser zu demonstrieren.

Poster 7 – Unsere Vorteile

Das siebte Poster stellt unsere differenzierten Dienstleistungen anhand von Fallbeispielen vor. Über die standardmäßige Qualitätskontrolle hinaus, Wir bieten an:

-

Stücklistenüberprüfung und Vergleich vor der Produktion

-

Firmware-Brennen und Trockeneisreinigung für PCBAs

-

Auf spezifische PCBA- und Kundendateien zugeschnittene Funktionstests

-

Auftragen einer Schutzbeschichtung

-

Reparatur basierend auf PCB-Schaltplänen

-

Röntgeninspektion von verdeckten Lötstellen wie BGA

-

Chip-Entkapselungstest

Diese Dienstleistungen verbessern die Produktqualität und demonstrieren unsere technische Stärke und Fähigkeit, vielfältige Kundenanforderungen zu erfüllen.

Poster 8 & 9 – Unsere Dienstleistungen

Poster acht betont unser Qualitätskontrollsystem, Personal abdecken, Ausrüstung, Materialien, Methoden, und Umwelt. Die visuelle Darstellung zeigt fortschrittliche Testgeräte wie AOI, Erstmusterprüfmaschinen, und Röntgensysteme für kritische Kontrollpunkte.

Poster neun ergänzt Poster vier durch die Demonstration von Chip-Entkapselungstests. In der realen Komponentenbeschaffung, Zeit- und Kostenbeschränkungen machen die Sicherung manchmal zu einer Herausforderung 100% Zuverlässige Komponenten. Die Einführung neuer Lieferanten kann Risiken bergen. Das Testen der Chip-Entkapselung ist eine proaktive Maßnahme, um gefälschte oder minderwertige Komponenten zu verhindern, Wir schützen sowohl Fully Hong als auch unsere Kunden.

Zusammenfassung:

Der Schlüssel zu wirkungsvollen Ausstellungsplakaten liegt in der Klarheit der Informationsvermittlung und der intuitiven visuellen Präsentation. Unsere Plakate erfüllen diese Grundvoraussetzungen, obwohl ihr Design schlicht bleibt. Im Vergleich zu den Plakaten mancher Unternehmen, die bei den Besuchern auch im Nachhinein Verwirrung über ihr Unternehmen hinterlassen 10 Minuten, Unsere vermittelt erfolgreich, was wir tun und welche Stärken wir haben.

Wir freuen uns über Feedback und Anregungen zu unseren Postern. Wenn Sie hochwertige Ausstellungsplakate gesehen haben oder Verbesserungsvorschläge haben, Bitte hinterlassen Sie einen Kommentar.

Hinterlasse eine Antwort