Aluminum PCB: Essential for Efficient Thermal Management

Aluminum PCBs (Printed Circuit Boards) have emerged as a critical component in electronic design, especially in applications that demand superior heat dissipation.

This article explores aluminum PCBs in detail, covering their production process, materials, applications, and a practical design guide.

What is an Aluminum PCB

An aluminum PCB, also known as a Metal Core PCB (MCPCB), uses an aluminum base material instead of the standard fiberglass (FR4).

These boards are ideal for high-heat environments such as:

-

High-power LEDs

-

Power supplies

-

Automotive electronics

Production Process of Aluminum PCBs

The manufacturing of aluminum PCBs involves precise, multi-step processes to ensure performance and reliability:

1️⃣ Base Layer Preparation

-

Aluminum substrate: Alloy 6061, 5052, or 1060

-

Dielectric layer: Electrical insulation + thermal conductivity

-

Copper foil: Conductive top layer

2️⃣ Lamination

-

Thermally conductive dielectric polymer is laminated to the aluminum base

-

Copper foil is then applied to create the circuit layer

3️⃣ Circuit Imaging

-

Photolithography transfers circuit design using UV light and photoresist

4️⃣ Etching

-

Unwanted copper is chemically removed to define trace patterns

-

Residual photoresist is stripped

5️⃣ Drilling & Plating

-

Holes are drilled for vias or mounting

-

Conductive plating ensures electrical connectivity

6️⃣ Surface Finishing

-

Apply finishes like:

-

ENIG (Electroless Nickel Immersion Gold)

-

HASL (Hot Air Solder Leveling)

-

OSP (Organic Solderability Preservative)

-

7️⃣ Solder Mask & Silkscreen

-

Solder mask protects copper traces

-

Silkscreen adds component labels and markings

8️⃣ Assembly & Testing

-

Components are soldered onto the board

-

Tests include:

-

Electrical continuity

-

Thermal performance

-

Materials Used in Aluminum PCBs

Each layer in an aluminum PCB plays a unique role in performance:

| Layer | Description |

|---|---|

| Aluminum Substrate | High thermal conductivity and mechanical strength (e.g., 6061, 5052) |

| Dielectric Layer | Electrically insulating, thermally conductive polymer |

| Copper Layer | 1–10 oz copper thickness, for high current and heat transfer |

| Surface Finish | ENIG / HASL / OSP for soldering and oxidation protection |

| Protective Layers | Solder mask and silkscreen for board protection and labeling |

Applications of Aluminum PCBs

Aluminum PCBs are widely used in industries demanding thermal control + reliability:

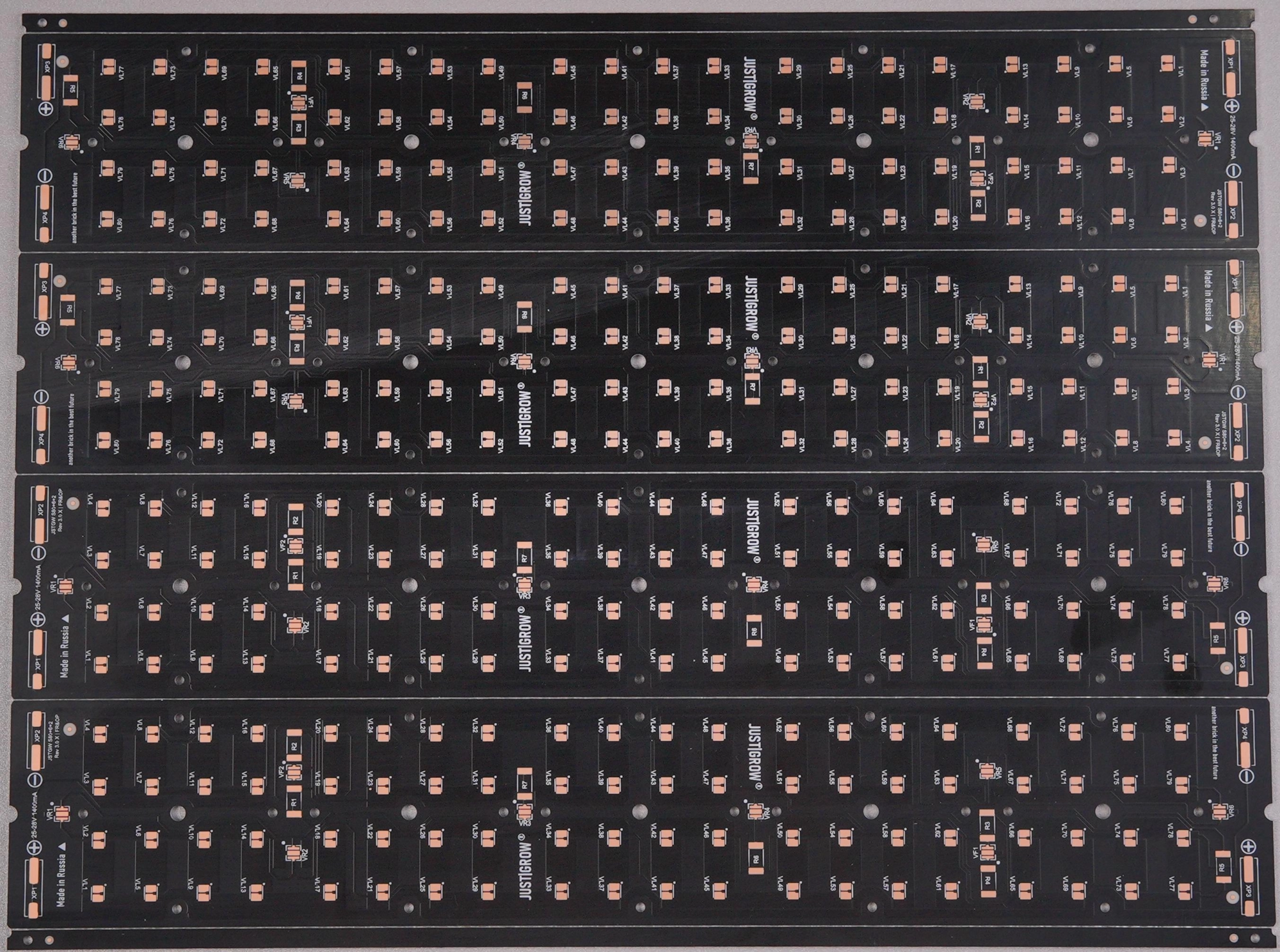

💡 LED Lighting

-

Street lamps, automotive headlights, architectural lighting

⚡ Power Electronics

-

Power supplies, inverters, and motor controllers

🚗 Automotive Electronics

-

Engine controls, dashboard electronics, brake light circuits

📱 Consumer Electronics

-

Laptops, TVs, audio amplifiers

🏥 Medical Devices

-

Surgical lighting, diagnostic equipment, patient monitoring systems

🌞 Renewable Energy

-

Solar inverters, wind power converters, smart grid systems

How to Design an Aluminum PCB

Proper aluminum PCB design ensures thermal efficiency and mechanical durability.

1. Define Requirements

-

Assess power & heat dissipation levels

-

Identify environmental conditions & protection levels

2. Select Materials

-

Choose aluminum alloy (6061, 5052…)

-

Define dielectric material and copper thickness

3. Optimize Circuit Layout

-

Use shorter high-current traces

-

Apply wider traces for power paths

-

Position components for even heat distribution

4. Thermal Management

-

Add thermal vias if required

-

Use thermal simulation tools to optimize

5. Design for Manufacturability

-

Align with manufacturer’s DFM rules

-

Confirm available materials and capabilities

6. Validate Through Testing

-

Simulate, prototype, and test in real-world environments

Conclusion

Aluminum PCBs are an indispensable solution for managing heat in high-performance electronics.

With advanced materials, streamlined production, and broad application potential, they provide:

-

Efficient thermal control

-

Durable structural support

-

High reliability in harsh environments

By following best design practices, engineers can unlock the full potential of aluminum PCBs in modern innovation.